POTD was repairing my Post drafting machine. Yeah, I can read a calendar and know it’s year 2020. . . In my defense, I hadn’t used it for about 30 years, but frankly find “old tech” still has its place on occasion.

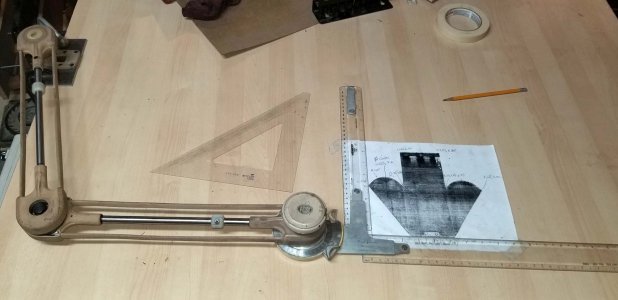

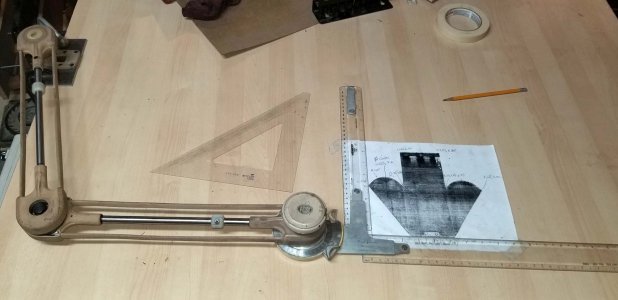

For those under 50 who have never seen one of these, mine is a Post/Mutoh drafting machine. The base is fixed to the drawing table. There are two swing arms with a pulley in between the two, plus pulleys on either end of the swing arms. The drafting detail (sorry, the proper name escapes me) has an infinitely adjustable base (in rotation) that can be locked into an angular position. Once locked in place, you can move the drafting head around the table and the X/Y scales stay parallel to your work. There’s a push button on the head that lets the scale rotate and lock into other angles in 15 deg. increments.

So, draw a base line on the X-axis and need to draw a 45 angle, push the button and swing the head to a 45, release the button and the head locks at that angle. There’s a protractor on the base with minutes graduations so you can read or draw angles in between.

When I work from an existing drawing, I tape it to the table and rotate the head until the bottom or side scale line up with the appropriate line, then lock the angle of the head. I have scales in fractional inches, millimeters and decimal inches.

I was going to use the drafting machine to dimension a computer scan of a part and discovered one of the pulley bands was snapped. The two arms have tensioning rods so the bands can be tightened on the pulleys. If they slip, you lose angular position. My guess is the bands are stainless and looked to be silver soldered together.

Busted band doesn't run too well on the pulley. . .

Looking at the other band, looked to be silver soldered together

My fix was to spot weld the band. My spot welder is plugged into a foot pedal so weld time is controlled by the tap time of my foot. I can’t adjust current, only weld time. Well, a tap of the foot for under a half-second blew through the band. I was able to get some really quick taps of the foot to weld around the big hole I made, so it’s holding for now. Cleaned up the inside surface with a Scotchbrite wheel.

Yeah, not my best spot weld. Hit a few more around the hole and it's holding fine

The tensioning is done with a steel rod with a bolt on one end. The bolt head has a keyway cut, to tighten the band you stick a nail or small Allen wrench through a hole in the base casting into the keyway, then turn the rod to unscrew the bolt.

The steel rod and bolt are used to tension the pulley band

Slip the band over the pulleys and turn the white knob to unscrew the bolt to tighten the band

Use an Allen wrench in the base to catch the key way in the bolt so it didn't turn with the rod

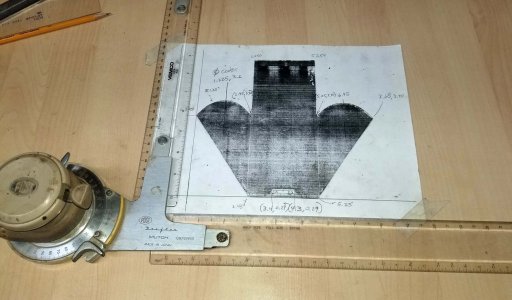

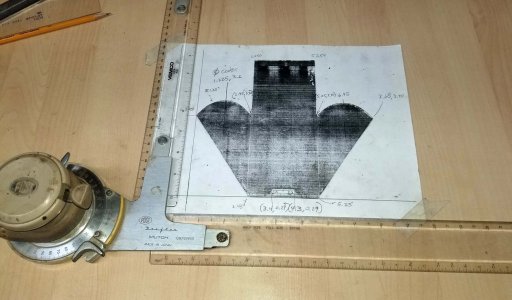

Works great again and works really well for me getting quick dimensions off an existing part. Pictures here are of a 4x scale Erector set part. I flattened an original part and scanned it on our computer, then scaled up in Photoshop for the hardcopy. I’ve got another thread showing the Erector set part I was making.

Yes, I know it's ancient technology, but I got the dimensions for this drawing in about 15 minutes. I'm accurate to about 0.010" which was "close enough" for my project. Still need to learn Fusion 360 or Solidworks one of these days. . .

Thanks for looking,

Bruce

bring it at the garage, i'll come in an hour. Got in it brakes feel good, called my brother and ask him when was the last time you drove this car outside of the city, oh i haven't in long time. So i took it on a mountain road got the brakes nice and hot to burn off all the glazing took it in the same inspection station and passed with no problems just user error haha.

bring it at the garage, i'll come in an hour. Got in it brakes feel good, called my brother and ask him when was the last time you drove this car outside of the city, oh i haven't in long time. So i took it on a mountain road got the brakes nice and hot to burn off all the glazing took it in the same inspection station and passed with no problems just user error haha.