POTD was some shop organization. I've had a small Thermolyne electric heat-treat furnace for years (4" x 4" x 8" chamber) which works great on small stuff. It takes about 30 minutes to heat to 1500 F or the temp needed to take drill rod to cherry red. It's 110V and doesn't pop a 20 A breaker, so figure it uses at most 2000 W. Power around here is $0.10 per kW hour, so a whopping $0.10 to take it to 1500 F in the half-hour. Much cheaper than using acetylene with a torch to take steel to temp.

Anyway, I picked up a larger furnace with a 9" x 9" x 15" chamber a year or two ago which has been setting on a roll-around work bench. Finally got around to making a cart to store both furnaces and get my chop saw back on the bench.

Didn't take any pictures of the construction, used 4" x 6"'s and deck hangers for the structure. Casters are rated at something like 800 lbs. each, so no problem with <400 lbs. of furnace on top.

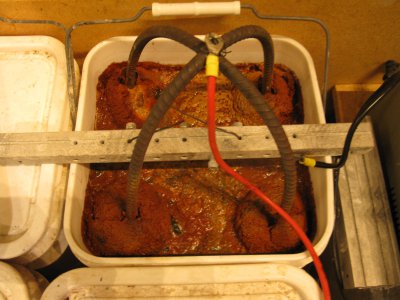

When I bought the furnace, the previous owner and I lifted it and set it in our Traverse. I'm guessing it has to be under 350 lbs. I rigged it for lifting using a couple pieces of 3/4" black pipe and shackles to nylon tie straps rated at 440 lbs. each. Drilled holes through some 3/4" plywood to space the pipes under the furnace. Yes, to all the safety Nazi's out there, these straps are not meant to be used for lifting. The ratchet strap ends were hooked to a gantry crane chain fall. The photos don't show it, but after ratcheting the straps to just lift the furnace (to check balance), I ran redundant safety cables from corner to corner in case the ratchet straps gave way.

Wood burns at 451 F, put a piece of Durock under the larger furnace just in case though it doesn't get very hot on the bottom side when fired up. Also threw the smaller furnace on top so the shop now has a mobile heat treat furnace station.

Thanks for looking.

Bruce