- Joined

- Nov 25, 2015

- Messages

- 8,372

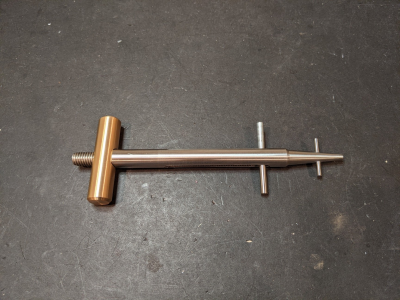

tore apart my new to me rotary table 6" cleaned it up internally, it needed new grease (not really)

I was going to use Moly when I realized what a waste since this doesn't spin at high speed, and I had half a gallon can of Lubriplate still.

so re-greased the worm, and pinion.. and just inspected.. I was in good shape, just need a 4mm screw to replace a missing one... not even sure why it's there...

I also enlarged the holes in the base, since it would not fit on my table.. my clausing table is small... 6" x 24... Don't believe what they say SIZE DOES MATTER.

Don't believe what they say SIZE DOES MATTER.

I was going to use Moly when I realized what a waste since this doesn't spin at high speed, and I had half a gallon can of Lubriplate still.

so re-greased the worm, and pinion.. and just inspected.. I was in good shape, just need a 4mm screw to replace a missing one... not even sure why it's there...

I also enlarged the holes in the base, since it would not fit on my table.. my clausing table is small... 6" x 24...