He was! He taught in the Mason, MI (two years) and Waverly districts (Lansing, MI) for 30 years. He was the youngest president of what was called the "Michigan Industrial Education Society" (now called Michigan Industrial and Technology Education Society), master teacher of the year honoree, and distinguished service award winner.

https://www.facebook.com/MITESmichigan/

Not many have his work ethic, I sure don't! Our family was watching TV on a Friday evening, dad cranked back his Laz-y-Boy chair and started sawing them off. Our neighbors probably heard him too! I woke him up around 8:00PM and said, "hey, if you're so tired, why don't you just go to bed? We're trying to watch the TV!" What I hadn't accounted for was his work week. He'd get up around 6:30 AM to get ready for school, get home around 4:30. Read the paper, eat dinner, watch Walter Cronkite, then head to the basement to work his second job: A photofinishing business named Hansen's Photo. He'd usually get to bed between 12:00 AM and 2:00 AM, then start it all over again with a 6:30 AM get up for school. He did that for 20 years. We miss him every day!

Bruce

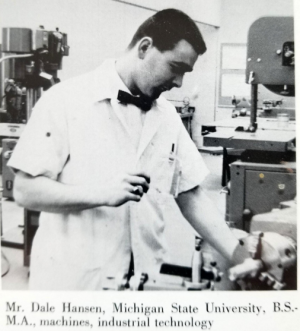

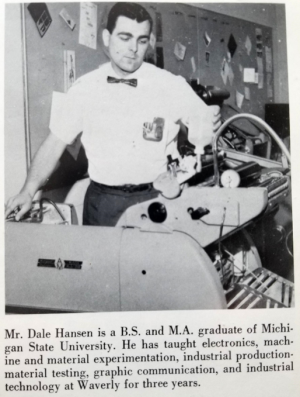

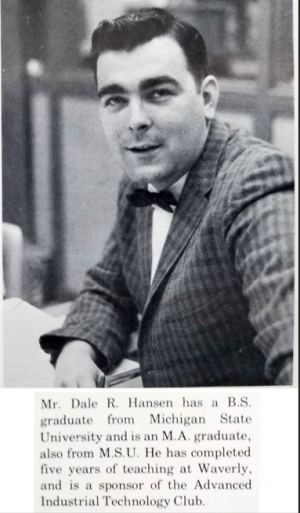

Circa around 1964; bow ties were clip-on, the thick eyebrows were real! And you wonder why he'd call me a smart *ss!

View attachment 468425

View attachment 468426

View attachment 468431

View attachment 468427