- Joined

- Oct 26, 2022

- Messages

- 31

All I know at this point is 3PH; but glad to have a recommended solution since I am completely new to VFD. I'll be definitely looking for guidance.That is a nice looking specimen Brad. I too just acquired a Colchester I'm picking up tomorrow and sweating having to move it with two strangers versus having my brother along as I normally would.

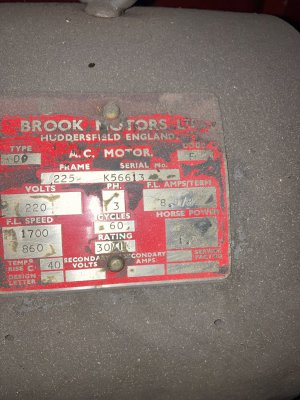

You dont mention what voltage the motor is, but most variable speed conversions out there are 240v 3 phase. I highly recommend the TECO-Westinghouse L510-203-H1-U if your motor is a 3 phase 240v motor, and your input voltage is 240v single phase. Lots of resources out there to help support you should you need help on the L510, versus the chinese VFDs, which so very often dont work as designed

Brad