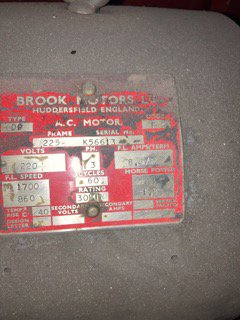

There are a couple of publications on owwm.com. A parts manual is listed under Clausing and a manual is listed under Colchester. Machine weighs 1550 lbs give or take. The lathe is driven by a two speed motor to get 16 speeds. Since there is no back gear, the two speed motor becomes important to getting the rpm range you want, absent the vfd. A vfd does not like two speed motors if they are of the Dahlander type rather than having two separate windings. That doesn't mean you can't run with a vfd but you can't switch between motor speeds while the vfd is powered up. You might want to talk to Mark or others about how to best deal with that. A downside of that configuration without a vfd is that there are few speeds above 750 - three I believe, so a vfd is a huge improvement if you sort out the wiring to isolate the vfd from the drum switch that drops out the poles on the motor. Motor is 8 pole and four pole. If Dahlander, four of the eight drop out in high and I would expect that to be the case. ask the seller about all of this and verify he is still running the original motor. If he swapped it out, see what is used now to get the 40-1800 rpm range.

Dave