Sure. I was wondering why they did not show. Thanks for letting me know.Heic files are Apple specific, can you please change the file type? Can't view the pictures.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Aluminum Meat Mallet

- Thread starter tredding

- Start date

- Joined

- Feb 27, 2014

- Messages

- 2,130

You should be able to re-center on the drilled hole. To avoid having to do that, If I am going to have to drill multiple holes (and not use the CNC capabilities), I dry to do all operations one hole at a time. Pilot; Drill; Tap. then move on to the next hole. This guarantees perfect alignment.

Thank you for the comment. My thoughts exactly. I did two test holes with the center drill, then drill and tap. I still have the imprecision. I had a grandson put a mower away and he hit the power feed on the end of the mill hard enough to knock it loose. That is one of the reasons I went back through the process of testing the alignment of the bed and vertical head. All seems correct. But now I have ordered a tramming tool to more precisely measure the alignment of the mill. We will eventually get it figured out.You should be able to re-center on the drilled hole. To avoid having to do that, If I am going to have to drill multiple holes (and not use the CNC capabilities), I dry to do all operations one hole at a time. Pilot; Drill; Tap. then move on to the next hole. This guarantees perfect alignment.

- Joined

- Jul 28, 2017

- Messages

- 2,386

If your problem was caused by knocking the mill out of tram the tilt should always have the same orientation.

Since you did each operation step on all of your mallet heads before moving on to the next op, it may be difficult to figure out how each head was installed in your vise, the most reliable way to check that theory out is to drill and tap a test piece and see how one of your handles looks when you screw it into the test piece.

If that is indeed the problem you may not need to re-make the heads. If it's flat, use the opposite side. The "bad" hole can be plugged with a short threaded piece that's glued in place then milled flat (after tram has been restored ) .

) .

Since you did each operation step on all of your mallet heads before moving on to the next op, it may be difficult to figure out how each head was installed in your vise, the most reliable way to check that theory out is to drill and tap a test piece and see how one of your handles looks when you screw it into the test piece.

If that is indeed the problem you may not need to re-make the heads. If it's flat, use the opposite side. The "bad" hole can be plugged with a short threaded piece that's glued in place then milled flat (after tram has been restored

All good thoughts and ideas. I believe the mill is out of tram. I believe Blondihacks, among others, have covered in detail how to test and correct a mill's tram.If your problem was caused by knocking the mill out of tram the tilt should always have the same orientation.

Since you did each operation step on all of your mallet heads before moving on to the next op, it may be difficult to figure out how each head was installed in your vise, the most reliable way to check that theory out is to drill and tap a test piece and see how one of your handles looks when you screw it into the test piece.

If that is indeed the problem you may not need to re-make the heads. If it's flat, use the opposite side. The "bad" hole can be plugged with a short threaded piece that's glued in place then milled flat (after tram has been restored) .

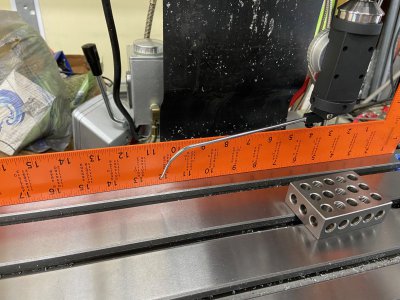

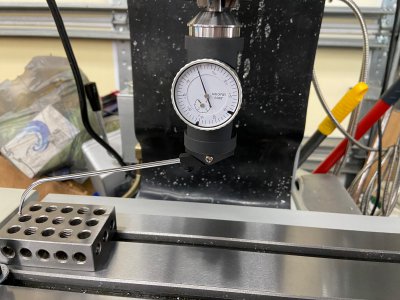

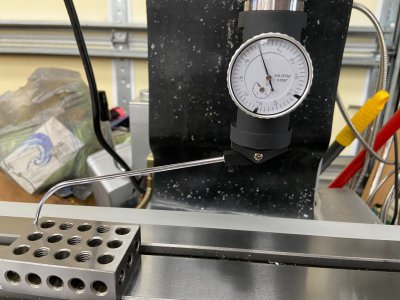

I tried to use the Center Indicator to evaluate the tram of my PM-728VT. The evidence the mill has lost tram is its inability to drill precision vertical hole in aluminum. I believe it was knocked out of tram when it was struck by a small mower being put away in the back of the shop. The mower was pushed past the mill striking the power feed hard enough for it to come loose at an angle.

Lesson learned, once the PM-1236 arrives the lathe and the mill will be aligned along a single wall and no longer stick out into a path through the shop.

I realigned the power feed and it appears to work well. Once I suspected the mill was out of tram I attempted to use the Center Indicator to measure by how much. First, I made sure there was no variance on the x, y, and z-axis of the vise. Then I clamped a precision machinist square in the vise to extend the vertical axis. I am about to follow the method shown in this video

. I also watched this multi-method video

. One of the subsequent videos I watched made a strong case for building a column indicator that provides two indicators,

.

I believe I am .001 out of alignment over about 12 inches. That does not seem like much. But I will correct the tram and see if I am able to drill a precision hole.

Lesson learned, once the PM-1236 arrives the lathe and the mill will be aligned along a single wall and no longer stick out into a path through the shop.

I realigned the power feed and it appears to work well. Once I suspected the mill was out of tram I attempted to use the Center Indicator to measure by how much. First, I made sure there was no variance on the x, y, and z-axis of the vise. Then I clamped a precision machinist square in the vise to extend the vertical axis. I am about to follow the method shown in this video

I believe I am .001 out of alignment over about 12 inches. That does not seem like much. But I will correct the tram and see if I am able to drill a precision hole.

Attachments

-

12%22 arm Center Indicator.jpeg539.5 KB · Views: 5

12%22 arm Center Indicator.jpeg539.5 KB · Views: 5 -

Error left end of the table.jpeg443.9 KB · Views: 5

Error left end of the table.jpeg443.9 KB · Views: 5 -

Zero left end of the table.jpeg470 KB · Views: 5

Zero left end of the table.jpeg470 KB · Views: 5 -

Zero left end of table.jpeg456.4 KB · Views: 5

Zero left end of table.jpeg456.4 KB · Views: 5 -

Zero right end of table.jpeg428.8 KB · Views: 5

Zero right end of table.jpeg428.8 KB · Views: 5 -

End of table error.jpeg512.7 KB · Views: 5

End of table error.jpeg512.7 KB · Views: 5 -

Zero spread Center Indicator.jpeg537.6 KB · Views: 5

Zero spread Center Indicator.jpeg537.6 KB · Views: 5

I tried to use the Center Indicator to evaluate the tram of my PM-728VT. The evidence the mill has lost tram is its inability to drill precision vertical hole in aluminum. I believe it was knocked out of tram when it was struck by a small mower being put away in the back of the shop. The mower was pushed past the mill striking the power feed hard enough for it to come loose at an angle.

Lesson learned, once the PM-1236 arrives the lathe and the mill will be aligned along a single wall and no longer stick out into a path through the shop.

I realigned the power feed and it appears to work well. Once I suspected the mill was out of tram I attempted us the Center Indicator to measure by how much. First, I made sure there was no variance on the x, y, and z-axis of the vise. Then I clamped a precision machinist square in the vise to extend the vertical axis. I am about to follow the method shown in this video

. I also watched this multi-method video

. One of the subsequent video I watched made a strong case for building a column indicator which provides two gauges,

.

Lesson learned, once the PM-1236 arrives the lathe and the mill will be aligned along a single wall and no longer stick out into a path through the shop.

I realigned the power feed and it appears to work well. Once I suspected the mill was out of tram I attempted us the Center Indicator to measure by how much. First, I made sure there was no variance on the x, y, and z-axis of the vise. Then I clamped a precision machinist square in the vise to extend the vertical axis. I am about to follow the method shown in this video

- Joined

- Jul 28, 2017

- Messages

- 2,386

Measure the angle between one of your mallet heads and handle. It it's inconsistent with your tram measurements there's something else going on.

If that's not accurate enough, another sanity check would be to install one of them in your vise and indicate off the handle as you raise the spindle.

If that's not accurate enough, another sanity check would be to install one of them in your vise and indicate off the handle as you raise the spindle.

Measure the angle between one of your mallet heads and handle. It it's inconsistent with your tram measurements there's something else going on.

I agree. No way are the head threads that crooked. You tapped in the mill, right? Do you have a thread relief next to the flange on the handle?

Good idea. I have an angle tool for doing just that. A few pictures are attached. The error in the verticle seems to be higher than indicated by my tram measurements. I seem to be seeing a 2° error in the verticle.Measure the angle between one of your mallet heads and handle. It it's inconsistent with your tram measurements there's something else going on.

If that's not accurate enough, another sanity check would be to install one of them in your vise and indicate off the handle as you raise the spindle.