- Joined

- Nov 23, 2020

- Messages

- 788

OK so the past few days have been about taking the machine apart when I am not working at my real job, and cleaning, planning, moving, staging for re-assembly. I still need to run power for the machine, and I would like to also run 110V after the on/off switch so I can kill power to machine and all accessories with one flip of a switch. Disassembly has been quite easy on this machine, and the resulting parts have been manageable solo.

Here are a few pictures of the process, and some commentary on the good and meh.

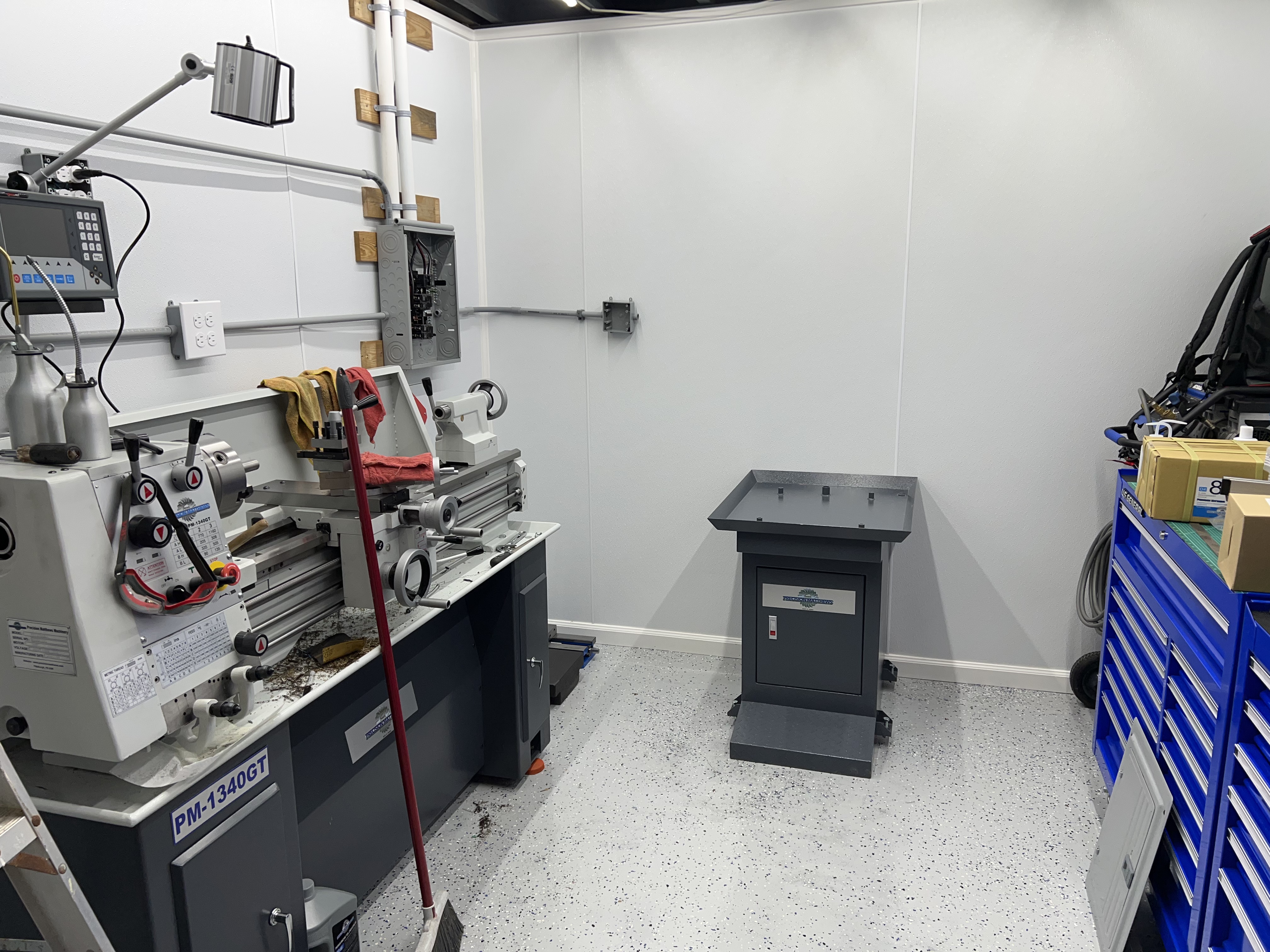

Mill is going to go here. I plan on running 4x10AWG runs through 1/2" Conduit on a dedicated 30A breaker for the machine, DRO and power feeds. Electric will go to a 220V switch first, to power everything up, then to a 220V outlet for the machent to plug into. After the plug I will likely run a bank of 4 outlets off one leg of the 220V for the machine. I am considering calling an audible though, and running 3/4" conduit so I can get unstitched 110V to the opposite wall first, and then backwire to a switch and then machine and bank of a separate 110V outlets.

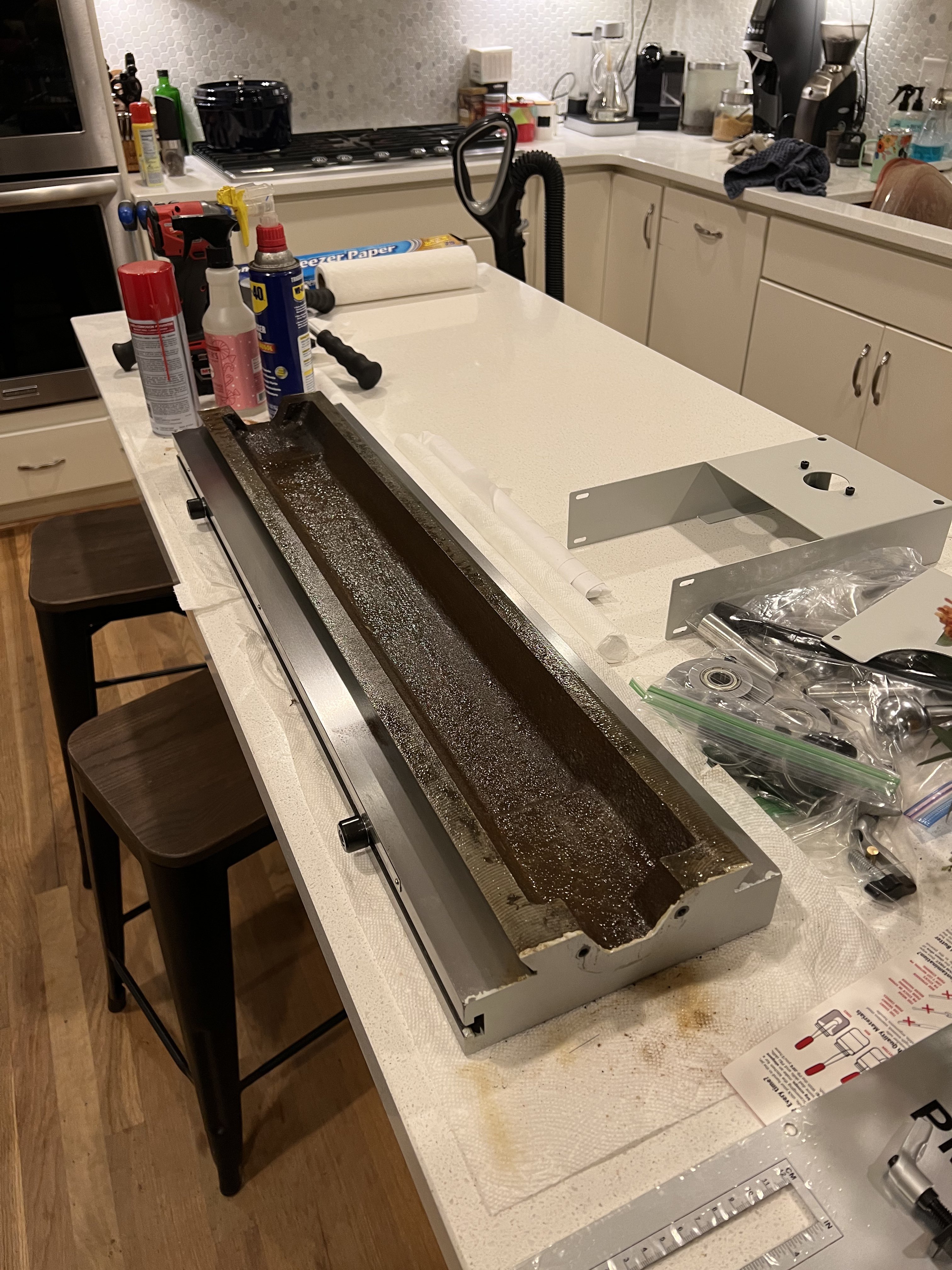

Here is the X table off the machine. The bottom of the casting was unpainted, and not coated, so it began to develop rust. I wire brushed this, and knocked off the loose rust, then wiped down with WD-40 to clean it

After cleaning the surface rust a bit, I treated both castings with Fluid Film. Mostly on the areas that will be hidden, and likely not to get any lubrication and or love once the machine is back together. I plan on repeating this process on the base and column. These 2 pieces will remain together for the final move to the basement. Planning on ratchet strapping that to a dolly, and 2 manning it down the exterior steps at my house. With everything else removed, it should be manageable.

Here are a few pictures of the process, and some commentary on the good and meh.

Mill is going to go here. I plan on running 4x10AWG runs through 1/2" Conduit on a dedicated 30A breaker for the machine, DRO and power feeds. Electric will go to a 220V switch first, to power everything up, then to a 220V outlet for the machent to plug into. After the plug I will likely run a bank of 4 outlets off one leg of the 220V for the machine. I am considering calling an audible though, and running 3/4" conduit so I can get unstitched 110V to the opposite wall first, and then backwire to a switch and then machine and bank of a separate 110V outlets.

Here is the X table off the machine. The bottom of the casting was unpainted, and not coated, so it began to develop rust. I wire brushed this, and knocked off the loose rust, then wiped down with WD-40 to clean it

After cleaning the surface rust a bit, I treated both castings with Fluid Film. Mostly on the areas that will be hidden, and likely not to get any lubrication and or love once the machine is back together. I plan on repeating this process on the base and column. These 2 pieces will remain together for the final move to the basement. Planning on ratchet strapping that to a dolly, and 2 manning it down the exterior steps at my house. With everything else removed, it should be manageable.