- Joined

- Feb 25, 2021

- Messages

- 3,129

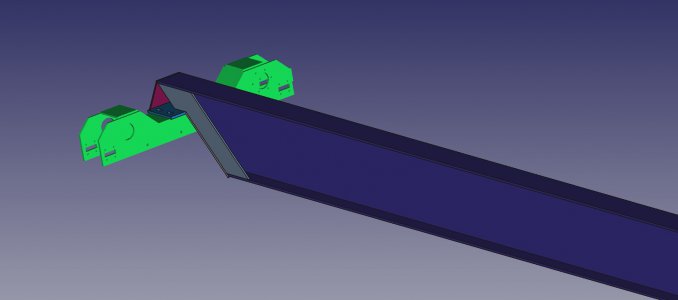

Bought the yellow paint I used on the boom lift for the actual bridge. Sherman Williams "Safety Yellow".Looks like some good progress. Nice new clean steel with fresh paint. I like it!

Thanks, for both the compliment and the advice to date.nice work, @rabler

Appreciate it, but I'm reserving "awesome" for when I get to use the bridge crane to actually lift something!That is awesome