- Joined

- Mar 26, 2018

- Messages

- 2,724

If nothing has changed, the table has an arch down the middle that was used to accommodate the original screw and nut. My Roton blocks fit without modification to the nut or table, but they don't have a flange.

I purchased a model of a BF20 back in 2014 which I have heavily modified to match my real G0704. I think it was $20. The model was nearly identical to my machine, but I definitely got bit a few times where I had a mounting hole slightly off position compared to the model. Taught me to check.

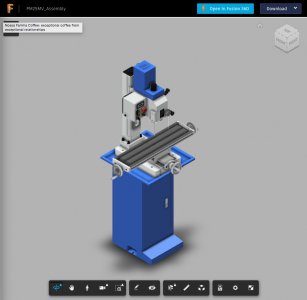

Looking online I now see a lot more free model options available. For example here is one: http://a360.co/2GrT4W0

All these machines are similar but not identical. Be careful what dimensions you assume to be correct.

I purchased a model of a BF20 back in 2014 which I have heavily modified to match my real G0704. I think it was $20. The model was nearly identical to my machine, but I definitely got bit a few times where I had a mounting hole slightly off position compared to the model. Taught me to check.

Looking online I now see a lot more free model options available. For example here is one: http://a360.co/2GrT4W0

All these machines are similar but not identical. Be careful what dimensions you assume to be correct.