- Joined

- Aug 6, 2015

- Messages

- 3,886

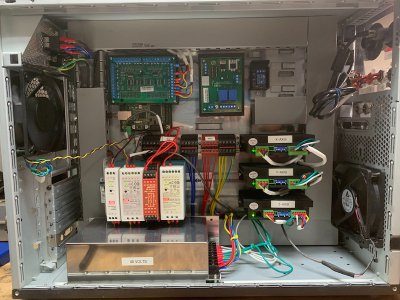

Stuff that happens when you let a project just sit... I installed the computer and the case with the electronics. All hooked up to make sure everything was still working... Quickly noticed that I installed the E-Stop to the case, but never connected the wires  ... no matter, just a test, let's keep going...

... no matter, just a test, let's keep going...

Everything moves... slowly... not sure how to increase the speed. I need to go back and learn everything again about the setup, wiring, using the software... sigh...

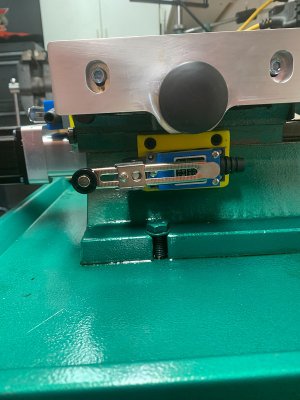

I also need to install (well, need to find them first, lol) the limit switches and do the wiring for those...

Everything moves... slowly... not sure how to increase the speed. I need to go back and learn everything again about the setup, wiring, using the software... sigh...

I also need to install (well, need to find them first, lol) the limit switches and do the wiring for those...