-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Group Project: Dividing Head - The Build

- Thread starter Flyinfool

- Start date

- Joined

- Mar 25, 2013

- Messages

- 4,614

The holes intersect less than 50%. I can fix that with silver solder and re-tapping. I was more concerned about the 45 deg angle of the lever.All is not lost yet.

How bad are they intersecting?

On the clamp the slot into the other side is still missing. There is nothing magic about the exact depth or width of the slot, It could be done with a saw if your slitting wheel does not reach that deep.

You can try it out on the Housing you have made to see if it will still clamp up tight without it?

As for the eccentricity of the driven gear once the set screw is tightened, Yes tightening the set screw will push it to one side, ASSUMING all parts are in tolerance and you use the worst case tolerance stack up the added backlash from the worst case would add ~0.002° of backlash, or ~0.00015 of linear travel at the pitch Dia. I personally don;t think I can even measure that repeatably.

Ideally the slits should be angled, The angle needed will be about 7.12°. The angle is not that critical that you need sine blocks, a plastic protractor will be plenty close. Even an eyeball guess and by gosh will be good.

My slitting saw wound not reach far enough to cut the other side of the clamp. I tested the clamp without the extended slit and it works very well. I have close diameter tolerances; I don't think it will be any issue. I could slit it with the bandsaw but it may not look as pretty.

Robert

- Joined

- Aug 3, 2017

- Messages

- 2,437

Got another hour and a half of shop time and decided to do operation #2 on the gears. That is, facing them to thickness.

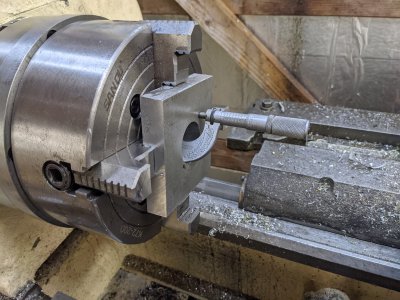

This step was pretty easy. First bit was to indicate it in, which I did mostly for practice. As a minor concern, I wanted to make sure my tool didn't hit the jaws when I reached the points:

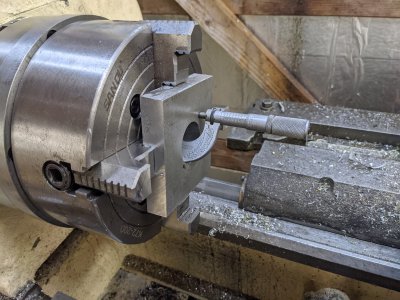

Next was measuring for thickness, which was a pain since my micrometers couldn't reach around the outside and my starrett only barely reached through the middle (when wound all the way out!).

Finally, face to size:

First one I did hit .753, so I set an indicator and did the rest to just about that figure! One turned out a little smaller since I had a chip get between it and a jaw, so I had to cut a few thou off. Still was .748, well within tolerances.

Next step is going to be to drill and cut the set screw so I can turn the OD. However, I don't have a great idea how to indicate in the center hole. My only thought is to waste a big piece of aluminum and cut it to 1.5" so I can hit it with the edgefinder, but I'm hoping there is a better way thoughts?

thoughts?

This step was pretty easy. First bit was to indicate it in, which I did mostly for practice. As a minor concern, I wanted to make sure my tool didn't hit the jaws when I reached the points:

Next was measuring for thickness, which was a pain since my micrometers couldn't reach around the outside and my starrett only barely reached through the middle (when wound all the way out!).

Finally, face to size:

First one I did hit .753, so I set an indicator and did the rest to just about that figure! One turned out a little smaller since I had a chip get between it and a jaw, so I had to cut a few thou off. Still was .748, well within tolerances.

Next step is going to be to drill and cut the set screw so I can turn the OD. However, I don't have a great idea how to indicate in the center hole. My only thought is to waste a big piece of aluminum and cut it to 1.5" so I can hit it with the edgefinder, but I'm hoping there is a better way

- Joined

- Apr 29, 2019

- Messages

- 2,059

OK we have a small change coming.

On the BOM the #8-32 x 3/4 HSFH screws will become #10-32 x 1/2 HSFH screws.

The 3 holes in the shifter housing for mounting the Index plates to the shifter Housing will be opened up to #10-32.

This will also require the 3 mounting holes in the index plates to be drilled and C'sunk for the #10 flat head screws.

I will post the revised drawings as soon as I can get them done.

There has been a major upheaval of things in my house, I have been laid off for a little over a year due to covid eliminating my job and some serious health issues. Well I just accepted a job offer and will now have a lot less time to play.

On the BOM the #8-32 x 3/4 HSFH screws will become #10-32 x 1/2 HSFH screws.

The 3 holes in the shifter housing for mounting the Index plates to the shifter Housing will be opened up to #10-32.

This will also require the 3 mounting holes in the index plates to be drilled and C'sunk for the #10 flat head screws.

I will post the revised drawings as soon as I can get them done.

There has been a major upheaval of things in my house, I have been laid off for a little over a year due to covid eliminating my job and some serious health issues. Well I just accepted a job offer and will now have a lot less time to play.

- Joined

- Jan 2, 2014

- Messages

- 8,852

Hey Brino! What parts are you making?

Wait. What?

None as far as I know!

I considered trying to contribute to either this or the clamp group project, but decided that shipping costs (on top of the time commitments) would include me out........

However, I am following along at home!

-brino

- Joined

- Oct 14, 2013

- Messages

- 984

I've still got two parts with no maker on the clamp build ;-)

That one is a "small flat rate box" kind of build, with only two shipments to pay for...

Sent from my SM-G892A using Tapatalk

That one is a "small flat rate box" kind of build, with only two shipments to pay for...

Sent from my SM-G892A using Tapatalk

- Joined

- Jan 2, 2014

- Messages

- 8,852

I've still got two parts with no maker on the clamp build ;-)

That one is a "small flat rate box" kind of build, with only two shipments to pay for...

If that was directed to me: I don't think "small flat rate box" translates into Canadian..........

-brino