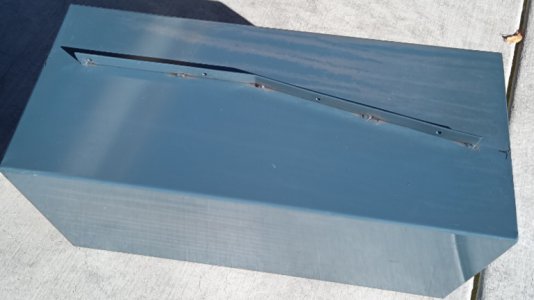

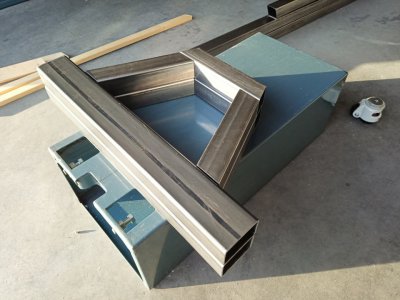

The stand is in pretty good shape, the support pedestals are 3/32" thick steel. the center webbing is damaged slightly.

The 5 carriage bolts were a useful end user modification that I'll incorporate with other modification's I make to the stand.

I am going to start cleaning them up today, and maybe start modifying them if there is time.

All cleaned up using purple power, The doors are pinned and easy to remove.

I am seriously considering the use of some Krylon spray paint to re-create this motif below on my lathe. I'll be modifying the stand and making a back splash anyway, so might as well make it look great and match my table saw too.

I could use some help figuring out what todays current best spray paint is to use... I have heard good things about Rust-Oleum Industrial Enamel Spray cans.. I know this subject is opening a can of worms, Not looking for Majic just what is known to work well.

My current rattle can paint research... So, I've never seen Seymour industrial MRO paint before, they make the claim on the can as being the best paint period. The other two brands we all know...! these are the paints that were recommended to me from each of the Tech Lines I called. these are industrial paints that are not found at your local Big Box stores.

I called Seymour tech dept two times and was told the paint is an oil-based product and would be a good fit for painting a metal lathe due to it being resistant to gasoline and most cutting fluids, only thing the tech was unsure of was how well it would hold up against impacts over time from tools and dropped objects. it is an oil-based alkyd enamel paint. -->

Seymour MRO spray paint.

I called Rust-oleum tech dept; They do not recommend their " professional" branded spray paint for machine tools, their recommendation is the "High performance" branded Industrial V2100 system enamel spray paint, it is an oil-based alkyd enamel paint that would be resistant to cutting oils, --> V

2100 Industrial spray paint.

I called Krylon tech dept 3 times because I was getting different answers from different techs until I got a tech that was willing to call and verify info with a department head, the Krylon industrial paints have subcategory's and even though the cans look the same and say industrial they are not the same, the Tough coat and Rust Tough are both in krylons industrial line up but are not the same. -->

Krylon Rust Tough spray paint

Last but not least the Krylon Tech also recommend I look into

DupliColors Engine Paint with Ceramic. I did not but it makes sense, engines have high heat, gas, oils and other chemicals to resist... I remember the good old days painting my intake manifolds. anyway, these paints are by no means the best paints for a Lathe, however since I don't want to buy a new spray rig and I'm just looking for quick, simple and reasonable DTM paint (Direct to metal - no primer needed), I think any of these High-end industrial paints would fill the bill for me.

If anyone knows the best rattle can paint to use on a lathe, please post it here... that way we will all know.

Its settled, I'll be the guineapig, take one for the team and try the Seymour MRO paint that I've never heard of, it says "the best paint period" right on the can - so it must be true, Right...!