I have taken a large chain link like a 200 and tore apart and gotten the rollers that would ride on the sprocket to make bushings. These are hardened rollers and would have to preheat first first and then weld with 6010 and then with a 7018. I skipped around when welding them in with the pin inside them and everything square before completely welding them up.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Making bushing & pins for a JD Dozer

- Thread starter Cabro32

- Start date

- Joined

- Sep 24, 2010

- Messages

- 3,096

You really need a portable line boring machine. Build up the hole and bore it back to original size and make a set of oil lite bronze bushings to fit. Once the holes are built back up and line bored then factory pins can be inserted. Or measurement can be taken from one and you can turn and weld your own as needed. Hope this helps and saves you a ton of cash instead of getting it done by someone else..

Bob

Bob

- Joined

- Sep 13, 2011

- Messages

- 271

Re: Making bushing & pins for a JD Dozer

You are welcome.

In the event of no bushing in the piece, I would leave the steel untempered. You would want the replaceable (least expensive) piece to wear. If nothing is available in A2, you could use O2 or W2 steel, whatever comes in the sized needed.

Hi Dan:

Good idea but problem is there is no bushing used. Pin in bracket with no bushing used.

- - - Updated - - -

flutedchamber:

Good info ,would expect that from Festus!!! Thanks

You are welcome.

In the event of no bushing in the piece, I would leave the steel untempered. You would want the replaceable (least expensive) piece to wear. If nothing is available in A2, you could use O2 or W2 steel, whatever comes in the sized needed.

- Joined

- Aug 7, 2013

- Messages

- 655

Re: Making bushing & pins for a JD Dozer

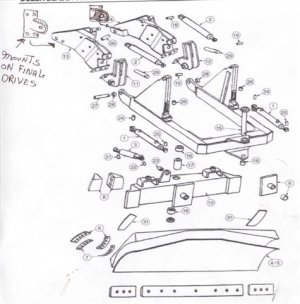

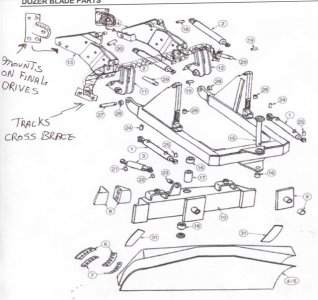

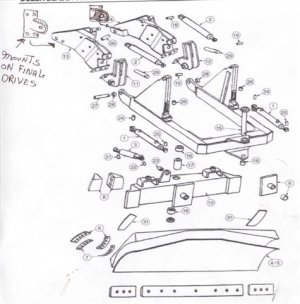

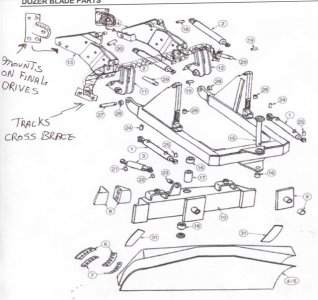

I thought what I have circled here was a bushing. Didn't at one point the OD share the same center as the ID? Or get you close?

Machinist buttons were mentioned. Tried searching the internet, didn't find anything. I'm guessing that they are simular to transfer punches and transfer screws. Turn a piece of steel to just the size of what the hole should be with an indicator point/center hole to locate the boring device.

What accuracy is required on these parts? This hole needs to be located to what other part?

Fun stuff to get the brain working....maybe a little!

Hi Dan:

Good idea but problem is there is no bushing used. Pin in bracket with no bushing used.

- - - Updated - - -

flutedchamber:

Good info ,would expect that from Festus!!! Thanks

I thought what I have circled here was a bushing. Didn't at one point the OD share the same center as the ID? Or get you close?

Machinist buttons were mentioned. Tried searching the internet, didn't find anything. I'm guessing that they are simular to transfer punches and transfer screws. Turn a piece of steel to just the size of what the hole should be with an indicator point/center hole to locate the boring device.

What accuracy is required on these parts? This hole needs to be located to what other part?

Fun stuff to get the brain working....maybe a little!

- Joined

- Sep 13, 2011

- Messages

- 271

Toolmakers buttons are fashioned, and fastened to a part so that the true center can be found by an indicator or height gauge. There is enough clearance between the button and fastener to allow movement needed to center the button.

The ID and OD of a boss are not always concentric.

The ID and OD of a boss are not always concentric.

- Joined

- Aug 24, 2013

- Messages

- 29

Re: Making bushing & pins for a JD Dozer

Jono:

Never heard of a toolmaker's button. Got a picture or a better description. Sounds like what I need.

Joe

- - - Updated - - -

usrjcro11

Why did you weld with 6010 first instead of starting with 7018?

Joe

- - - Updated - - -

Rbeckett:

I agree that I need a line boring machine but because of the cost for a one time operation that isn't going to happen. So I am trying to see if it can be done another way.

Joe

- - - Updated - - -

Festus:

This bracket holds a pin that doesn't move. The piece that fits between the ears moves and has the bushing in it. How it is wore so bad is another question.

Joe

Indicating off a close fitting plug should be good enough- it'll ignore the the worst out of round bit.

If you must work to a dimension, eg so a linkage doesn't bind, you'll need to make some toolmaker's buttons.

Jono:

Never heard of a toolmaker's button. Got a picture or a better description. Sounds like what I need.

Joe

- - - Updated - - -

I have taken a large chain link like a 200 and tore apart and gotten the rollers that would ride on the sprocket to make bushings. These are hardened rollers and would have to preheat first first and then weld with 6010 and then with a 7018. I skipped around when welding them in with the pin inside them and everything square before completely welding them up.

usrjcro11

Why did you weld with 6010 first instead of starting with 7018?

Joe

- - - Updated - - -

You really need a portable line boring machine. Build up the hole and bore it back to original size and make a set of oil lite bronze bushings to fit. Once the holes are built back up and line bored then factory pins can be inserted. Or measurement can be taken from one and you can turn and weld your own as needed. Hope this helps and saves you a ton of cash instead of getting it done by someone else..

Bob

Rbeckett:

I agree that I need a line boring machine but because of the cost for a one time operation that isn't going to happen. So I am trying to see if it can be done another way.

Joe

- - - Updated - - -

You are welcome.

In the event of no bushing in the piece, I would leave the steel untempered. You would want the replaceable (least expensive) piece to wear. If nothing is available in A2, you could use O2 or W2 steel, whatever comes in the sized needed.

Festus:

This bracket holds a pin that doesn't move. The piece that fits between the ears moves and has the bushing in it. How it is wore so bad is another question.

Joe

- Joined

- Aug 24, 2013

- Messages

- 29

Re: Making bushing & pins for a JD Dozer

Dan:

What you have circled is a reinforcing collar that is welded on each ear. Good thinking on the ID and OD having the same center, I will have to look an see if the collars were machined.

Machinist button must be as you stated. Accuracy hast to be close so when every thing is pinned together there is no slop or binding.

Joe

I thought what I have circled here was a bushing. Didn't at one point the OD share the same center as the ID? Or get you close?

View attachment 62442

Machinist buttons were mentioned. Tried searching the internet, didn't find anything. I'm guessing that they are simular to transfer punches and transfer screws. Turn a piece of steel to just the size of what the hole should be with an indicator point/center hole to locate the boring device.

What accuracy is required on these parts? This hole needs to be located to what other part?

Fun stuff to get the brain working....maybe a little!

Dan:

What you have circled is a reinforcing collar that is welded on each ear. Good thinking on the ID and OD having the same center, I will have to look an see if the collars were machined.

Machinist button must be as you stated. Accuracy hast to be close so when every thing is pinned together there is no slop or binding.

Joe

- Joined

- Aug 24, 2013

- Messages

- 29

Toolmakers buttons are fashioned, and fastened to a part so that the true center can be found by an indicator or height gauge. There is enough clearance between the button and fastener to allow movement needed to center the button.

The ID and OD of a boss are not always concentric.

Festus:

With you there, sure would like to see a button.

Joe

- Joined

- Aug 7, 2013

- Messages

- 655

Re: Making bushing & pins for a JD Dozer

This part looks like NO 11 or 12.

Dan:

What you have circled is a reinforcing collar that is welded on each ear. Good thinking on the ID and OD having the same center, I will have to look an see if the collars were machined.

Machinist button must be as you stated. Accuracy hast to be close so when every thing is pinned together there is no slop or binding.

Joe

This part looks like NO 11 or 12.