-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

My PM1236

- Thread starter darkzero

- Start date

- Joined

- Nov 16, 2012

- Messages

- 5,596

The machine turns native US threads -meaning, the leadscrew is US. The machine is capable of cutting metric threads by using the supplied gears but, the procedure is slightly different. All machines which natively cut US threads follow the same procedure to cut metric.

Ray

EDIT: Please see post 13 of this thread. The documents therein describe the threading and other aspects of the machine.

http://www.hobby-machinist.com/show...-Asked-Questions)?highlight=PM1236+Frequently

Another EDIT: It's possible that by Spindle Threads, you mean rear spindle spider area. Those are 16 TPI -not M1.25. Off hand, I don't know the diameter.

Ray

EDIT: Please see post 13 of this thread. The documents therein describe the threading and other aspects of the machine.

http://www.hobby-machinist.com/show...-Asked-Questions)?highlight=PM1236+Frequently

Another EDIT: It's possible that by Spindle Threads, you mean rear spindle spider area. Those are 16 TPI -not M1.25. Off hand, I don't know the diameter.

Good evening - Hey on the spindle threads on the PM-1236 metric or standard?

Thanks,

Woodrow

Last edited:

- Joined

- Nov 27, 2012

- Messages

- 7,854

Good evening - Hey on the spindle threads on the PM-1236 metric or standard?

Thanks,

Woodrow

If you did mean the threads on the rear of the spindle.... I could of sworn I listed it in the spider post. Maybe that was in another forum.

Gary (MHRIP) came up with 1 5/8"-16, I measured myself & also came up with the same. That's what I cut & it fit great.

EDIT: Oh I guess I did here but it was a couple of posts after in post #22.

Last edited:

1 5/8"-16 is what I used. I didn't have wire's to check the size of my threads so I had to go by pure depth of the thread. Worked perfect. Was for a stop for my 5C collet closer and not a spider. The threads on my spindle are a little rough. I ran a stone of the tops to clean up the crests but there isn't much to fix the threads without purchasing a $100 tap to chase them. I'm now thinking I need to make a spider as well for when I don't want to cut up long pieces of stock so I can just get busy making parts.

As for threading I almost refuse to cut metric threads. Such a PITA if you are threading to a shoulder. I need to make a spindle hand wheel to be able to turn the spindle manually.

As for threading I almost refuse to cut metric threads. Such a PITA if you are threading to a shoulder. I need to make a spindle hand wheel to be able to turn the spindle manually.

- Joined

- Nov 27, 2012

- Messages

- 7,854

Darkzero

Beautiful job! may i ask what taiwain company actually made the lathe? I have been searching for answers and presently engaging matt at machinetool

Thank you. I don't know which CM Matt currently uses to manufacture this model but it is made in China. The PM1340GT is made in Taiwan.

I would not be surprised if Matt does not wish to disclose that information but regardless the lathe is built for Matt's specifications/options.

- Joined

- Nov 27, 2012

- Messages

- 7,854

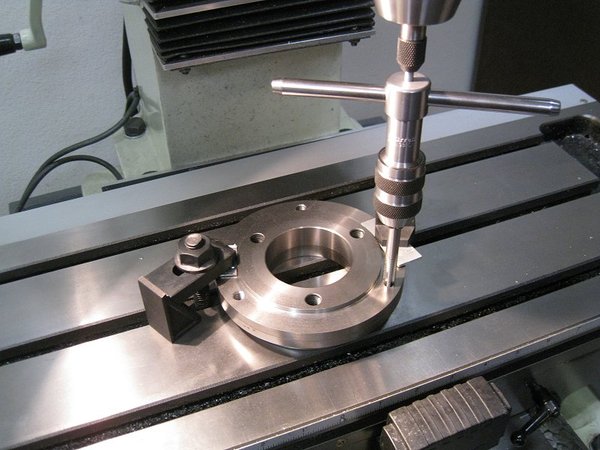

I bought a couple of ER40 plates last year, finally got around to mounting one to the lathe. Pretty happy with the way it came out. Measuring the run out on the inside taper where the collet sits the needle barely even moves at all.

Made a handle for holding it while tightening/loosening. Also showing a 1" Lyndex ER16 extension that I scored for cheap.

Made a handle for holding it while tightening/loosening. Also showing a 1" Lyndex ER16 extension that I scored for cheap.

- Joined

- Sep 2, 2013

- Messages

- 378

DarkZero

Your speed charts didn't convert on the new forum software.

I use your threads for reference you do such a good job of documenting.

Rick

Your speed charts didn't convert on the new forum software.

I use your threads for reference you do such a good job of documenting.

Rick

- Joined

- Nov 27, 2012

- Messages

- 7,854

DarkZero

Your speed charts didn't convert on the new forum software.

I use your threads for reference you do such a good job of documenting.

Rick

Thanks for pointing that out to me Rick. Looks like XF doesn't support chart formats with their editor. I had to convert them to photos. All fixed now and the ones in my other threads too.