- Joined

- Jul 28, 2017

- Messages

- 2,370

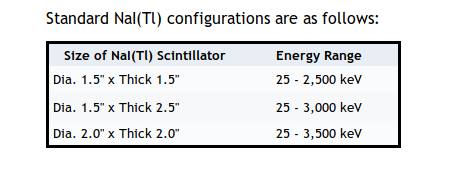

I have some additional information to share. I found a source for new scintillator crystals here. The price seems "reasonable" for non-eBay stuff, and you don't have to ask for a quote to get the price! The link shows listings for a different scintillator, but that's because of stuff I learned while browsing the Theremino web site. They have a document showing the use of a SiPM coupled to a LYSO(Ce) scintillator The nice thing about LYSO is that it isn't hygroscopic at all.

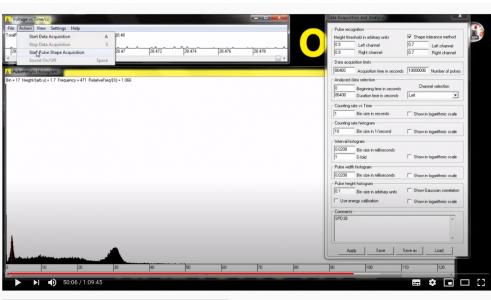

And, speaking of Theremino, they have a fairly detailed explanation of their approach to squeezing as much resolution out of their system as possible. If you believe them, you want to get the detector pulse into the digital domain as soon as you can. Their comments discouraging the use of analog pulse-capturing H/W are pretty compelling. They use an interpolation scheme to find the signal peak, and also algorithms to detect "bad" pulses coming out of the detector. They use a 2-pole passive RC lowpass filter to slow down the pulses coming from the detector, and some other signal conditioning circuitry as well. This also improves the SNR, which, according to them, is a Good Thing.

Unfortunately, their English documents leave a lot to be desired as far as clarity goes. Mostly because either they used some sort of translation program, or the writer (clearly) is not a native English speaker/writer. For instance, I think they are using "pictures" in some cases where we would use "pixels". But I could be wrong....

And, speaking of Theremino, they have a fairly detailed explanation of their approach to squeezing as much resolution out of their system as possible. If you believe them, you want to get the detector pulse into the digital domain as soon as you can. Their comments discouraging the use of analog pulse-capturing H/W are pretty compelling. They use an interpolation scheme to find the signal peak, and also algorithms to detect "bad" pulses coming out of the detector. They use a 2-pole passive RC lowpass filter to slow down the pulses coming from the detector, and some other signal conditioning circuitry as well. This also improves the SNR, which, according to them, is a Good Thing.

Unfortunately, their English documents leave a lot to be desired as far as clarity goes. Mostly because either they used some sort of translation program, or the writer (clearly) is not a native English speaker/writer. For instance, I think they are using "pictures" in some cases where we would use "pixels". But I could be wrong....