- Joined

- Nov 26, 2017

- Messages

- 1,517

Sounds like you have this well thought out. Your shop sounds like it is going to be set up the right way.

amazing isn't it.This space looks so big vacant, but when you start filling in all this stuff it starts getting cramped fast.

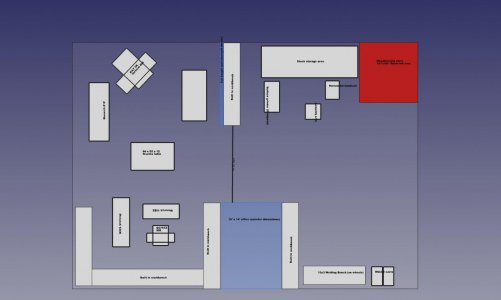

Slightly more detailed layout.

Yellow is windows.

Red is electrical features

Green is bridge crane uprights.

Corners: storage for lathe and mill tooling, toolcarts, etc. Misc knooks and crannies will fill up. Nature abhors a vacuum.@rabler

On the layout, how do you visualize using the isolated corners created by the placement of the 612, the K&T and the VMC?

I understand that the layout is a work in progress, but it looks like those areas are substantial square footage with very limited access.

I don't remember if this has been discussed before, regarding the bridge uprights, were any special provisions incorporated in the slab configuration for additional support at those locations?

I should add having room off the end of the 612 in both directions is intentional. Turning either through the headstock or via a steady rest can lead to something extending past the lathe footprint. I also found out the hard way that taking the apron apart requires a fair amount of room off the tailstock end of the lathe to remove the leadscrew and other various apron rods. I have had to move that lathe around quite a bit, and moving 5 ton machines is not trivial, so I'm hoping to avoid that@rabler

On the layout, how do you visualize using the isolated corners created by the placement of the 612, the K&T and the VMC?