- Joined

- Sep 22, 2021

- Messages

- 115

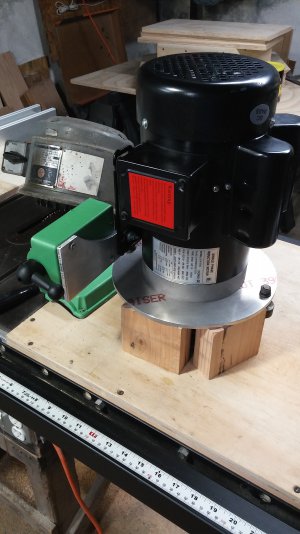

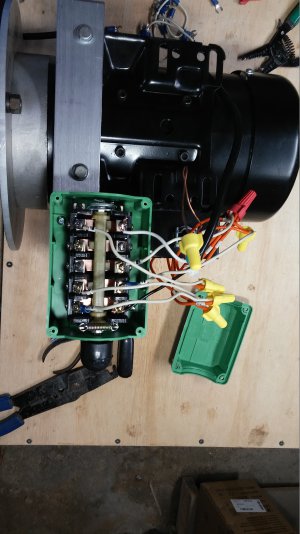

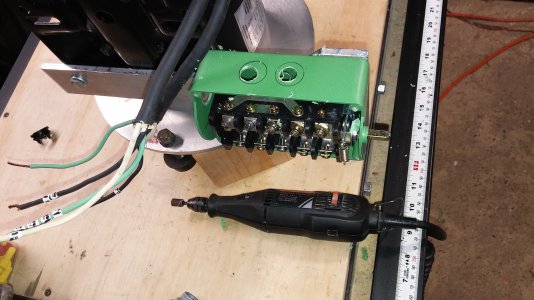

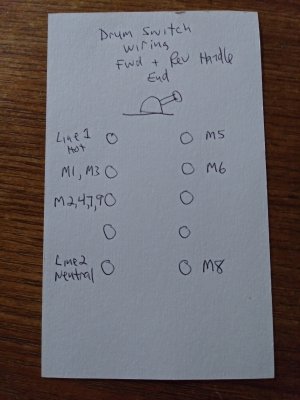

Next, I made a mounting bracket for the Drum Switch and I mounted it on the motor. The switch mount was made from a scrap piece from the new motor mounting plate (sorry, no photo, but I will share an image that shows it). The switch is closer to the front of the machine than the original that was built into the BP Motor, but the switch isn't in the way of the brake handle. Then I reached out to Ulma Doctor. for his help wiring the switch.