- Joined

- Jan 8, 2020

- Messages

- 177

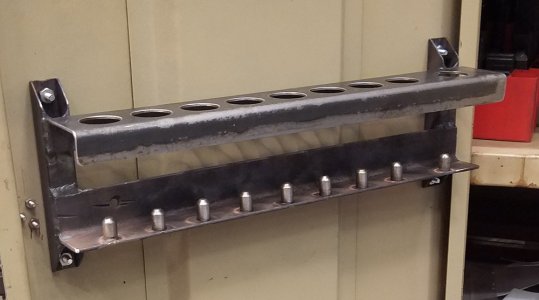

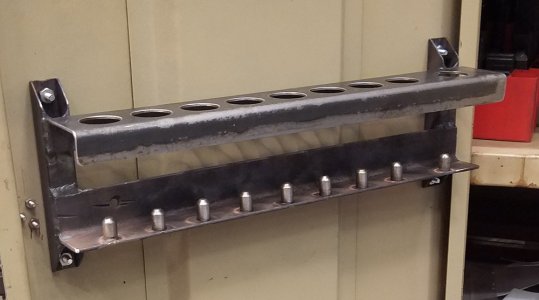

Made a rack for my R8 collets and drill chuck.

My Bridgeport lives in a shared workshop so I can't just leave everything out when I go home. I have a cabinet next to the mill for mill tooling and anything that isn't bolted to the table goes back in each day. I've been storing the collets and chuck on a shelf but they take space and it is annoying to find the right collet. So I made this rack that fits on the inside of the cabinet door. It is vertically located so the collets and chuck fit between two shelves, but it only uses about 1 inch of the shelf depth so really has no impact on the other items on the shelf. At the bottom right of the photo below you can see the old collet boxes, they are going away and will free up some shelf space.

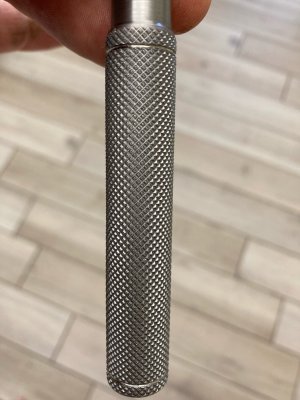

I've never liked racks that support the collets by their reference surfaces (the taper and the straight section at the back). This rack supports the weight on the back of the collet. The holes in the upper cross member are just below the taper, and the pins on the lower cross member are a sloppy fit in the drawbar thread minor diameter.

My Bridgeport lives in a shared workshop so I can't just leave everything out when I go home. I have a cabinet next to the mill for mill tooling and anything that isn't bolted to the table goes back in each day. I've been storing the collets and chuck on a shelf but they take space and it is annoying to find the right collet. So I made this rack that fits on the inside of the cabinet door. It is vertically located so the collets and chuck fit between two shelves, but it only uses about 1 inch of the shelf depth so really has no impact on the other items on the shelf. At the bottom right of the photo below you can see the old collet boxes, they are going away and will free up some shelf space.

I've never liked racks that support the collets by their reference surfaces (the taper and the straight section at the back). This rack supports the weight on the back of the collet. The holes in the upper cross member are just below the taper, and the pins on the lower cross member are a sloppy fit in the drawbar thread minor diameter.

Last edited: