I then mounted it in a little vise and sawed using a jewelry saw.

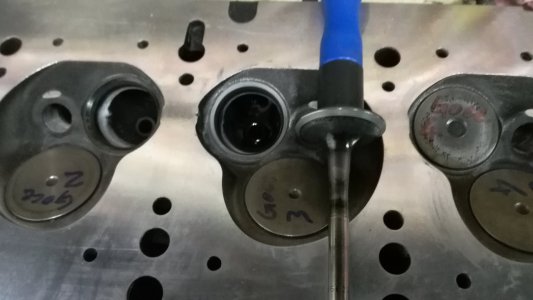

Everything was looking just great…. Took the little vise out of the bench vise… and then I dropped it. And of course, the vise/collet landed on the ground with the collet hitting the ground first. It totally bent the heck out of the collet.

I was bummed. Oh well

Everything was looking just great…. Took the little vise out of the bench vise… and then I dropped it. And of course, the vise/collet landed on the ground with the collet hitting the ground first. It totally bent the heck out of the collet.

I was bummed. Oh well

Attachments

-

D5CF80F0-0736-4857-B2D5-2C4F75109D66.jpeg89.8 KB · Views: 38

D5CF80F0-0736-4857-B2D5-2C4F75109D66.jpeg89.8 KB · Views: 38 -

0D2561C0-9286-4F75-B748-9D9E3AA299AB.jpeg199.8 KB · Views: 35

0D2561C0-9286-4F75-B748-9D9E3AA299AB.jpeg199.8 KB · Views: 35 -

83BA128E-6439-4529-9443-A85BAFDE944A.jpeg104.4 KB · Views: 37

83BA128E-6439-4529-9443-A85BAFDE944A.jpeg104.4 KB · Views: 37 -

5ABFF83D-3699-4ECC-8F53-AC34EDA1D8F3.jpeg57.8 KB · Views: 35

5ABFF83D-3699-4ECC-8F53-AC34EDA1D8F3.jpeg57.8 KB · Views: 35 -

B96F66B0-8E00-461D-97E0-7D830837F40F.jpeg65.1 KB · Views: 35

B96F66B0-8E00-461D-97E0-7D830837F40F.jpeg65.1 KB · Views: 35 -

A5F8BDE3-BE6E-404C-B375-C705D811AED1.jpeg93.4 KB · Views: 34

A5F8BDE3-BE6E-404C-B375-C705D811AED1.jpeg93.4 KB · Views: 34

Last edited: