- Joined

- Dec 18, 2019

- Messages

- 6,446

Hardly a project of a "full day", but pretty pleased with saving a laser printer from the dumpster. Foolish printer would jam on every page - religiously. The printer had effectively become inop, jamming all the time. I was about to smash the thing with a sledge hammer.

Digging deep into the bowels of the internet I found this was a common problem for Brother laser printers, especially the HL2040 series. The issue is a piece of rubber that exudes over time and becomes sticky. This piece of rubber is only 6mm long and maybe 20mm long and is buried inside the printer. You can't easily remove it without a lot of disassembly. The original rubber was a stop for a solenoid associated with paper feeding. When the arm sticks, it feels a lot of paper - jamming the printer.

I found a link (which pointed to a youtube video). Have to say, the video was one of the first ones that I have ever gotten motion sickness from. It was terrible. Both the link and the video actually don't show exactly where that little pad is, nor what to do! Eventually this blind gopher got the nut. Here's the link. https://nobblynoel.wordpress.com/2012/10/25/brother-hl-2040-laser-printer-repair-solutions/

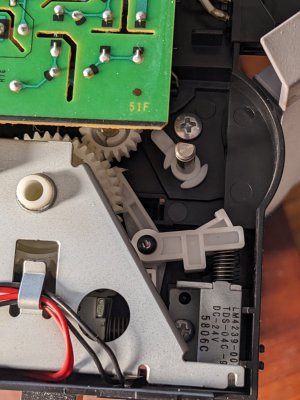

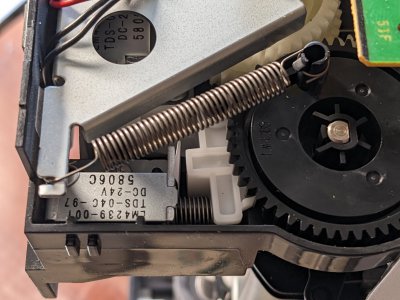

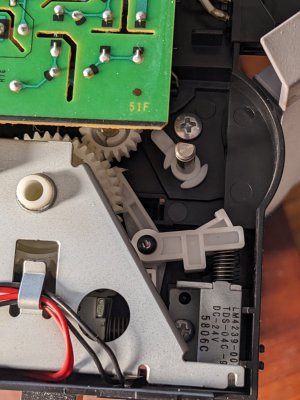

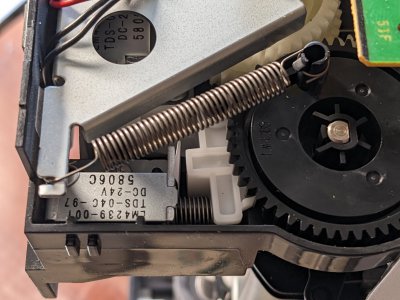

But here's the location of what you have to fix.

If you zoom in on the flat surface on the solenoid in the bottom right hand corner - there's a black rubber pad that acts as a stop for the white lever. The lever was sticking on the pad. Here's the fix, get ready for this, a slip of paper, about the size of the pad. Since the pad is sticky, the paper sticks to it!

Now the lever doesn't stick! And the paper feeds without jamming any more. Hot diggety, it's like having a new printer again! Cost to fix, an almost barf from the video and a 6 x 20 mm slip of paper. Pretty pleased with this. Really didn't want to have to buy a new printer - especially one's with the same design defect.

Digging deep into the bowels of the internet I found this was a common problem for Brother laser printers, especially the HL2040 series. The issue is a piece of rubber that exudes over time and becomes sticky. This piece of rubber is only 6mm long and maybe 20mm long and is buried inside the printer. You can't easily remove it without a lot of disassembly. The original rubber was a stop for a solenoid associated with paper feeding. When the arm sticks, it feels a lot of paper - jamming the printer.

I found a link (which pointed to a youtube video). Have to say, the video was one of the first ones that I have ever gotten motion sickness from. It was terrible. Both the link and the video actually don't show exactly where that little pad is, nor what to do! Eventually this blind gopher got the nut. Here's the link. https://nobblynoel.wordpress.com/2012/10/25/brother-hl-2040-laser-printer-repair-solutions/

But here's the location of what you have to fix.

If you zoom in on the flat surface on the solenoid in the bottom right hand corner - there's a black rubber pad that acts as a stop for the white lever. The lever was sticking on the pad. Here's the fix, get ready for this, a slip of paper, about the size of the pad. Since the pad is sticky, the paper sticks to it!

Now the lever doesn't stick! And the paper feeds without jamming any more. Hot diggety, it's like having a new printer again! Cost to fix, an almost barf from the video and a 6 x 20 mm slip of paper. Pretty pleased with this. Really didn't want to have to buy a new printer - especially one's with the same design defect.