- Joined

- Feb 2, 2017

- Messages

- 1,234

Looks great!

Looks great!

If you do much fabricating, you'll be amazed at how much quicker it will be to clean up and remove stock. After I finished mine, I kicked myself for not having one long ago. Bench grinders, even 1 HP units are no match for these machines. I was afraid the belts would be expensive and always needing replacement but found out that is not the case.Finally up and running...

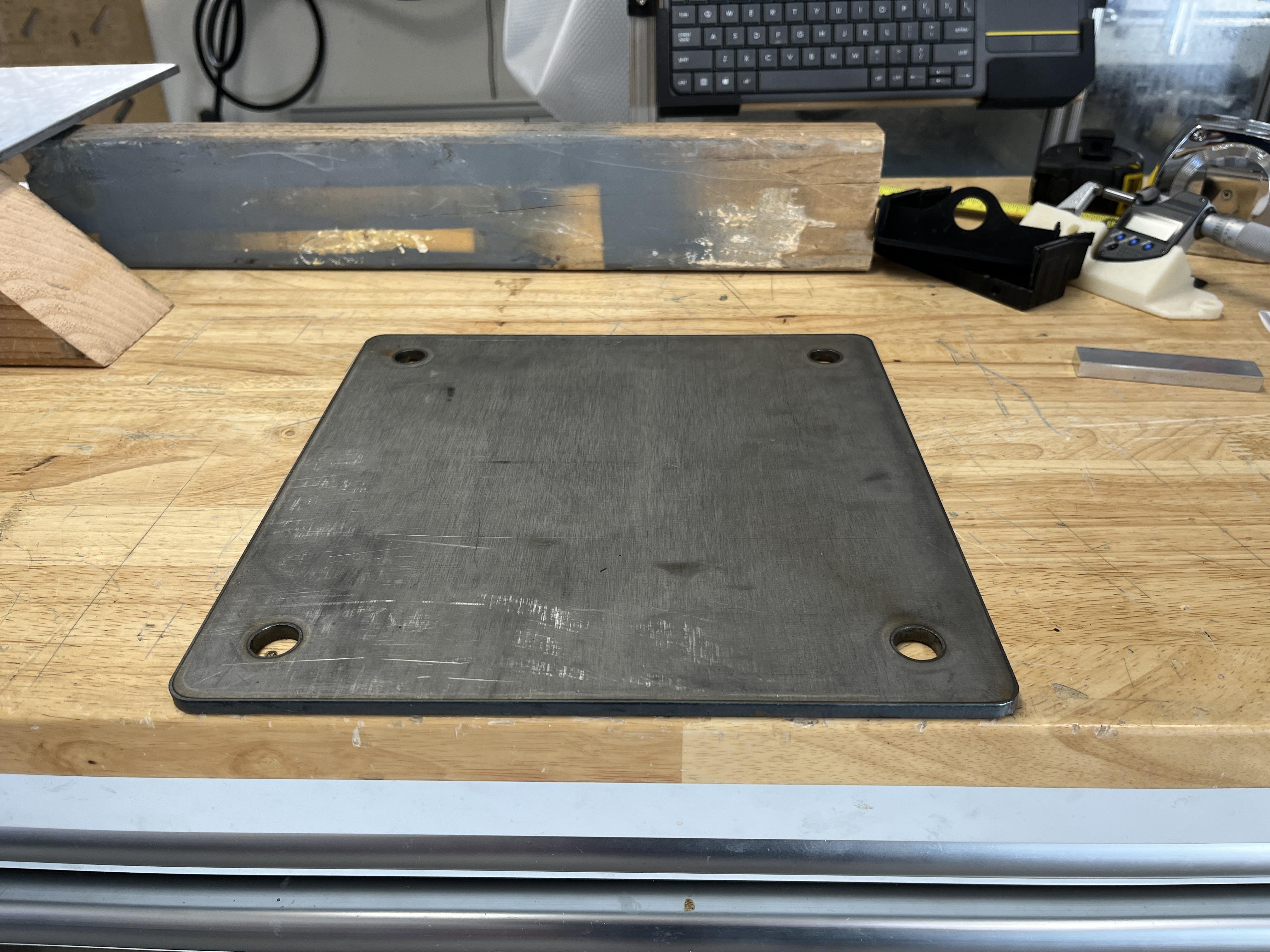

I dont really do much of anything yet. This was my first fabrication project. My son's welder, a garage sale drill press and another garage sale disk sander are all the tools I had, so this seemed to be the next logical step.If you do much fabricating, you'll be amazed at how much quicker it will be to clean up and remove stock. After I finished mine, I kicked myself for not having one long ago. Bench grinders, even 1 HP units are no match for these machines. I was afraid the belts would be expensive and always needing replacement but found out that is not the case.

I use good coarse belts and remove the tension as much as I remember to.

Aaron