- Joined

- Sep 10, 2022

- Messages

- 930

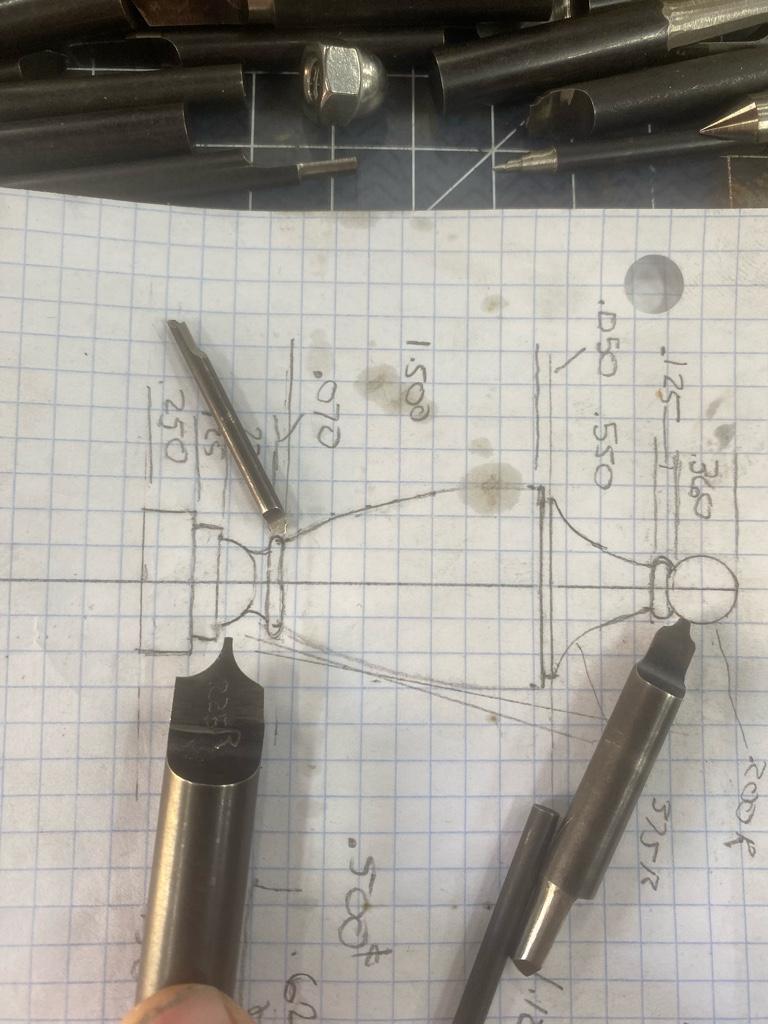

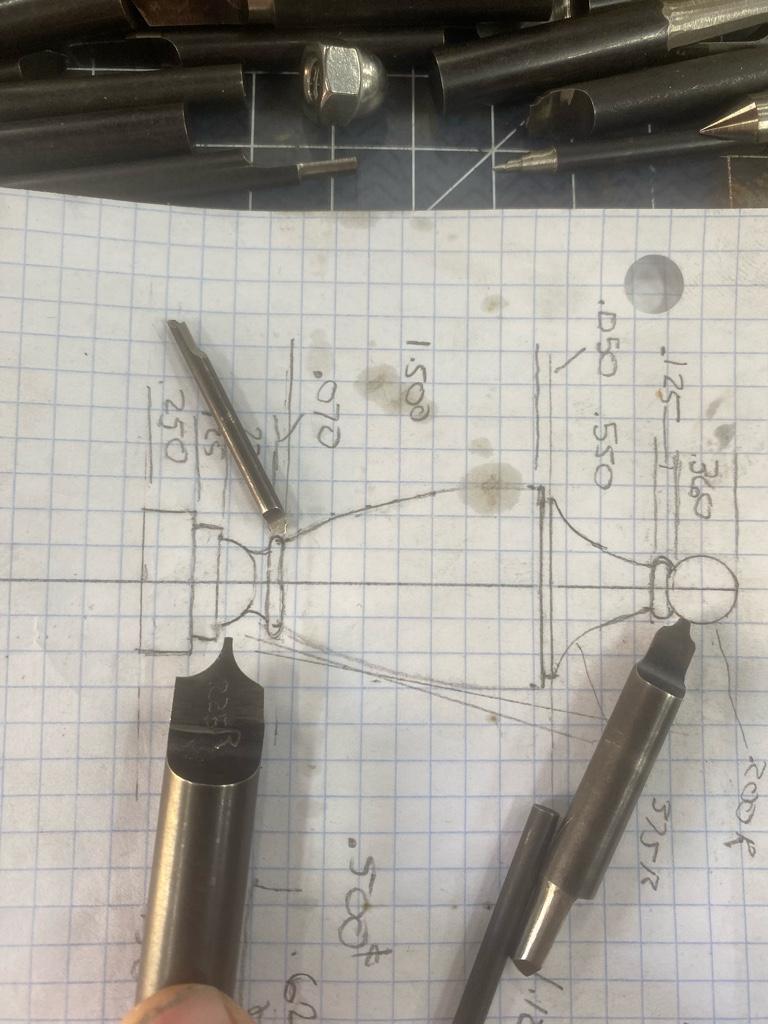

I finished the test finial. I looked through my old single lip cutters and found stuff to work. Only had to modify 1. I used my bell cutter attachment for the end ball.

I will finish sanding it up decent later today.

Cutting oil is my blood.

I will finish sanding it up decent later today.

Cutting oil is my blood.