- Joined

- Nov 25, 2015

- Messages

- 8,296

I have that too, but mine is on a 3/8 shaft, and I use it when that works for me.No love from me.

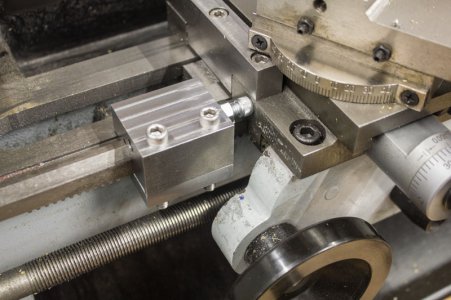

I replaced the linkage arms with a noga arm. I got the idea from Oxtools- Tom Lipton.

Sent from my iPhone using Tapatalk

Different tools for different problems.