- Joined

- Nov 25, 2015

- Messages

- 8,296

Yea, none of us have had any luck with that. I'm sure most have tried to let it do it on it's own .... (procrastinate)After waiting for this car to put itself together i had to do it myself.

Yea, none of us have had any luck with that. I'm sure most have tried to let it do it on it's own .... (procrastinate)After waiting for this car to put itself together i had to do it myself.

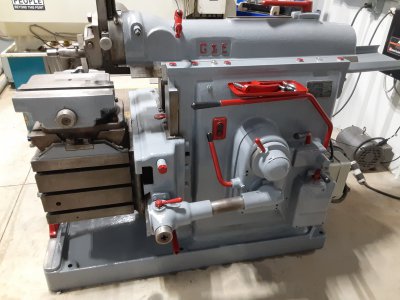

A heavy 9? I didn't know one existed. I knew a heavy 10.. pics? BTW nice chuck... nice backplate.I bought a lovely Pratt Burnard 6" 3 jaw adjust Tru at an auction last summer, but haven't made a thread dial for the SB heavy 9 so I could make a back plate. Anyway, I traded a vise for a rotary table and a 1-1/2"-8 tpi back plate that had a really thick boss.

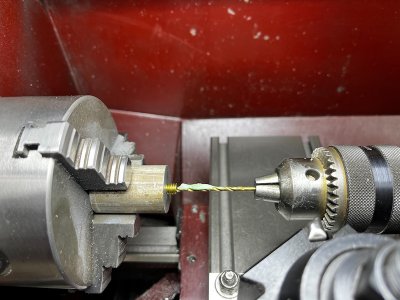

So I faced the boss end that had the recess, turned it round and cut the recess for the new "back". Then turned down the boss for the adjust Tru part, faced it and turned down the OD to that of the chuck. Located the holes, drilled and taped them then fitted the chuckView attachment 406833View attachment 406834View attachment 406835View attachment 406836

Chucked up a gauge pin and got it to repeat to within a thou total run out at different diameters. That'll do!

It was from before the workshop 9 (A/B/C) came out in the early 30s. The precision series used the same bed and carriage/ apron for both the 9 and 10" lathes, but differed in the headstock/ cross slide/ tailstock (maybe the QCGB, but I'm not sure). So the "heavy" 9 has the same 7" wide bed as the "heavy" 10 does. It's pretty heavy and stout for its size, I think about 500lb?A heavy 9? I didn't know one existed. I knew a heavy 10.. pics? BTW nice chuck... nice backplate.