-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

POTD- PROJECT OF THE DAY: What Did You Make In Your Shop Today?

- Thread starter wachuko

- Start date

- Joined

- Apr 23, 2018

- Messages

- 6,525

This starts as a gift, and ends as a POTD.

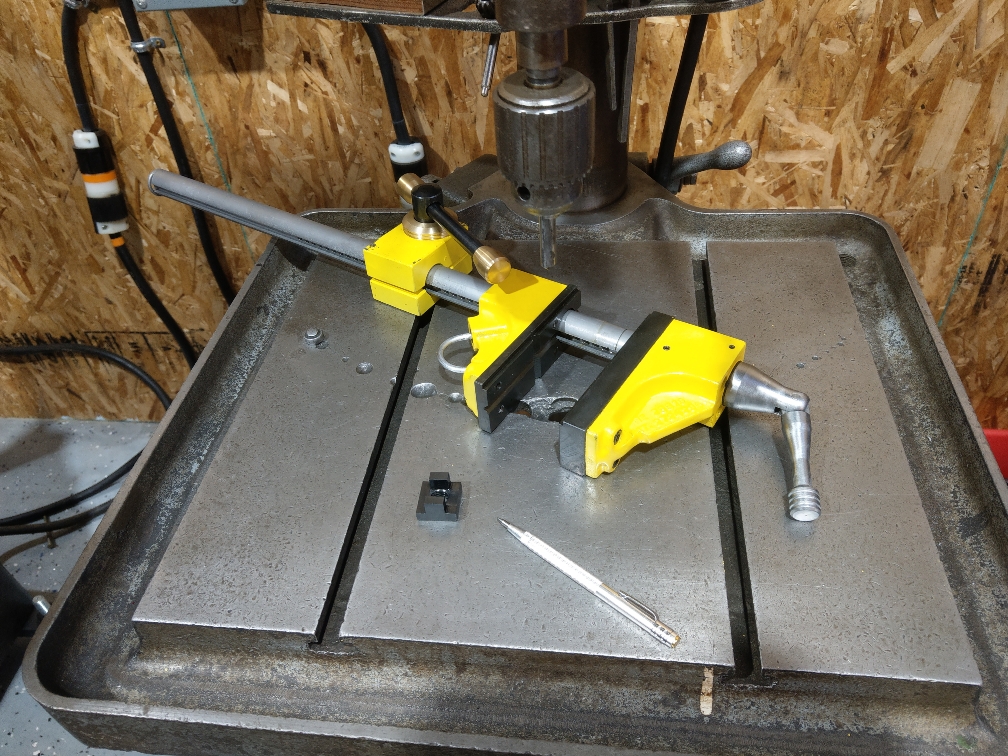

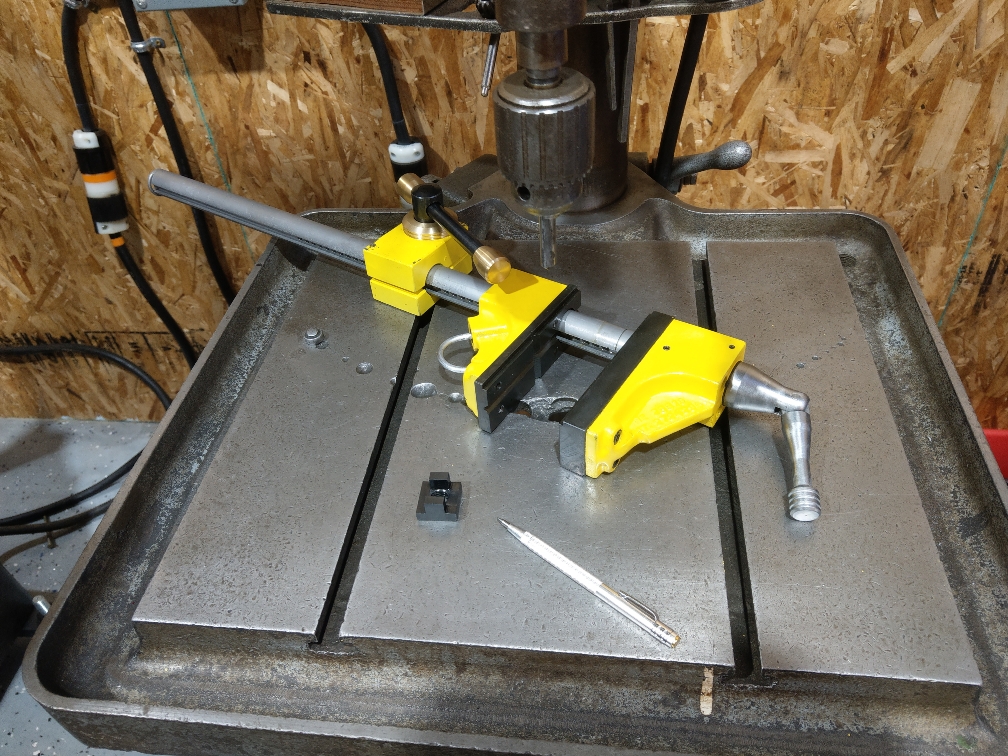

My dad pieced together most of an unmolested Wahlstrom Float Lock vise, and decided I had the better drill press for it. He cherried it up, made up the table clamp assy from scratch, and sent it to me. Sweet! So I made up some T nuts, a brass escutcheon washer to match dad's clamp handle, trimmed the bolt to fit, and bam! Instant, versatile, and rigid clamping! Thanks, Dad!

My dad pieced together most of an unmolested Wahlstrom Float Lock vise, and decided I had the better drill press for it. He cherried it up, made up the table clamp assy from scratch, and sent it to me. Sweet! So I made up some T nuts, a brass escutcheon washer to match dad's clamp handle, trimmed the bolt to fit, and bam! Instant, versatile, and rigid clamping! Thanks, Dad!

- Joined

- Nov 25, 2015

- Messages

- 8,293

I have been laying low since my plantar fasciitis has been raging. I can't stand long. So I decided to buy stuff and modify the shop. I need more space... WHO DOESN'T? I figured I'd practice what I preach. I used to use this box I had for the grinders, but it wasn't working for me then. I had it on a Jr. WorkBench I got at a garage sale. Seems like I was wasting the workbench. Also my Tool/Surface grinder went in that spot. The one I replaced it with also wasn't working out. It just didn't allow me to store stuff underneath... And the reality is , you don't want stuff under your grinders, the grit sucks... But I thought about it, and figured if one of my carts can go under the grinders when not in use I would gain some space. So I attached the footing to the wall, it can also fold out of the way if I need to move some big equip in or out. I used door hinges to support it. I painted it for more light, and changed the light above to a Walmart 5000 lumen shop light , and as a bonus, my trays that hold the projects I am working on can sit on top of the grinders instead of on my shelves where they upset the storage issue. So a win win..

The old one fit two grinders between two doors on a lazy susan with locking screws. The new/old allows side by side.

They are in the same spot, but I get more use out of it.

Lazy Susan

New use of old box hung on wall.

The old one fit two grinders between two doors on a lazy susan with locking screws. The new/old allows side by side.

They are in the same spot, but I get more use out of it.

Lazy Susan

New use of old box hung on wall.

- Joined

- May 3, 2017

- Messages

- 1,997

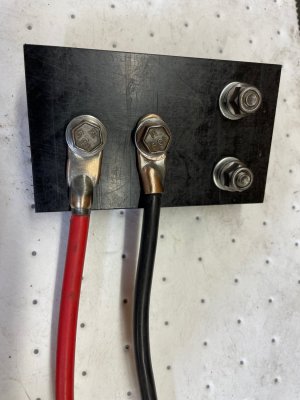

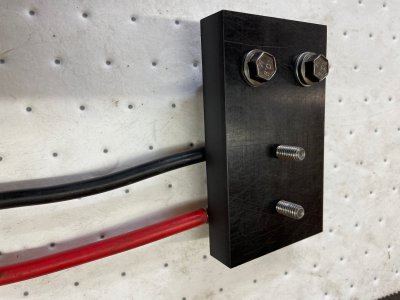

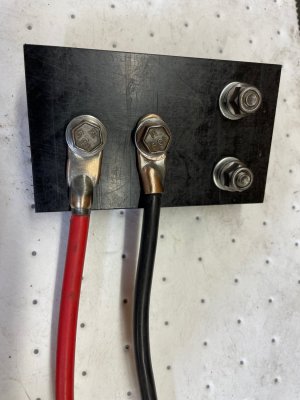

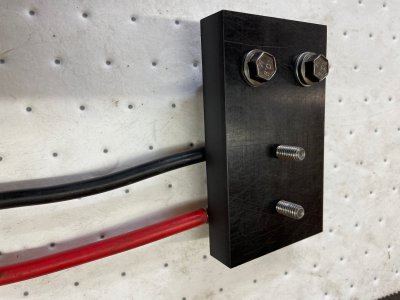

Made this battery terminal box for a friend of mine. He uses a few battery powered attachments with his four-wheeler, such as a spray tank, but they're difficult to hook up because of placement of the battery. He mounted this terminal block at a convenient place on the four-wheeler. Now, he can just hook up and go. The block is made of 3/4" Delrin; hardware is M8-1.25; battery cables are standard automotive (6 gauge I think). And the real beauty of this is that every part, including the cables, are scrap and leftovers taking up space in my shop from other projects. Win-win.

Regards

Holes for battery cables are threaded; through-holes for mounting hardware:

Mounted on his four-wheeler; the battery is located behind the flap at bottom of photo - a real pain to access with alligator clips:

Regards

Holes for battery cables are threaded; through-holes for mounting hardware:

Mounted on his four-wheeler; the battery is located behind the flap at bottom of photo - a real pain to access with alligator clips:

- Joined

- Oct 16, 2019

- Messages

- 6,570

I used to suffer from plantar fasciitis something awful. What really did the trick for me was two things:I have been laying low since my plantar fasciitis has been raging. I can't stand long.

1) I cut a piece of 1.5 ABS pipe about six inches long and put a layer of duct tape around it. When I was sitting reading or what have you I would roll my foot over the pipe to massage the tendon.

2) I did two minutes of heel raises every night. Bare feet on a non-carpeted floor.

After a week or two of this I never had a bout of it again.

- Joined

- Nov 25, 2015

- Messages

- 8,293

I have been rolling a tennis ball and then following up with a frozen water bottle.I used to suffer from plantar fasciitis something awful. What really did the trick for me was two things:

1) I cut a piece of 1.5 ABS pipe about six inches long and put a layer of duct tape around it. When I was sitting reading or what have you I would roll my foot over the pipe to massage the tendon.

2) I did two minutes of heel raises every night. Bare feet on a non-carpeted floor.

After a week or two of this I never had a bout of it again.

I'll add the heel raises. Was not told to do that.. thanks.

My issue is flat feet, and my orthotics beat me up over time.. I'm watching Aukai's progress to see how that goes. I would love to stop using the orthotics.

- Joined

- Nov 20, 2018

- Messages

- 709

Not really a huge project, more like a request from a friend. I have a friend who built a new Myer's Manx dune buggy. yes the company is still in business and producing bodies and kits. He flew down to look at the product offerings and even got to chat with Bruce Myers himself. He is still running the company at 80 years old.

I helped with the engine overhaul and gave random advice during the project. He replaced the original camshaft with new and wanted to make a desk lamp out of the old one. He didn't have any way to drill a hole through the cam to run the wires through, so I offered to take a stab at it.

I chucked it in the lathe and got it to run true, then added the steady rest and with a little patience I got it drilled. Then took it to the mill and plunged an end mill through the cam gear for the wire. He just wanted to cut a notch, but I like the idea of a hole to hold the wiring in place.

I helped with the engine overhaul and gave random advice during the project. He replaced the original camshaft with new and wanted to make a desk lamp out of the old one. He didn't have any way to drill a hole through the cam to run the wires through, so I offered to take a stab at it.

I chucked it in the lathe and got it to run true, then added the steady rest and with a little patience I got it drilled. Then took it to the mill and plunged an end mill through the cam gear for the wire. He just wanted to cut a notch, but I like the idea of a hole to hold the wiring in place.