- Joined

- Feb 2, 2017

- Messages

- 1,234

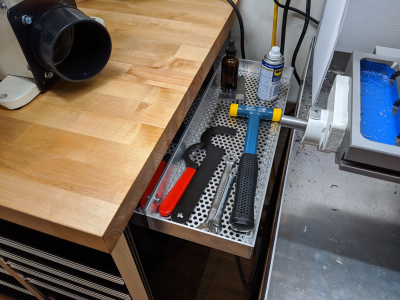

Got 'er done. Took quite a bit longer than the hour I'd planned, but most of the extra time was futzing with the non-standard wheels--drilling new holes in the sheet metal, squaring them off for the carriage bolts, then realizing the holes in my spacers weren't big enough for the square portion of the carriage bolts, etc. Pretty impressed with the quality for the money.Grab pics while you are out there of your pretty spacers. There is nothing like machine eye candy to make the day better.

Should allow me to keep most of my lathe tooling stored rather than scattered about the shop. Need to fab 5C collet rack for the top section (the people I bought the 5C collets shipped it in that rack and it didn't do so well, plus it's too tall for the compartment), and figure out a better place for my tool holders.

![IMG_0434[1].JPG IMG_0434[1].JPG](https://www.hobby-machinist.com/data/attachments/292/292530-dc130c59e9aeae5146d01b63209c0adc.jpg)

![IMG_0435[1].JPG IMG_0435[1].JPG](https://www.hobby-machinist.com/data/attachments/292/292531-50cb0814ba7e32552f76f6794314d9a1.jpg)