- Joined

- Jan 9, 2023

- Messages

- 239

I really appreciate the info and guidance. The lube systems will be the first thing I take care of when I dive into it. Thanks for letting me pick your brain!

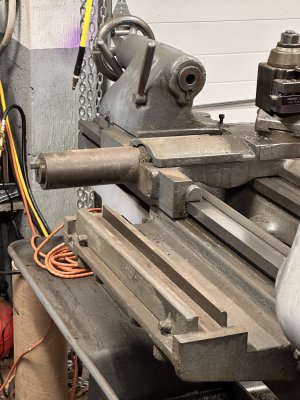

Thanks for the pictures. First time I've actually seen the earlier version up close. I think you are right. The large bearing was probably a shop modification. I would think you could adapt to my version. It looks like the earlier version didn't release the block but rather just allows it to slide off the end if the taper attachment was set at zero angle. Is that correct? Pratt & Whitney's attachment on either version was a stationary type. I have to keep in mind when I respond to you that there are difference between our versions. Let me know if I'm helping or not.I was wondering about the taper attachment’s connection to the shoe on my machines version of it and wondered if I could find any video or picture of it. I also went back out to study it again and found amongst other things in the pan what looks like a shop made shoe utilizing a bearing instead of a block.

View attachment 436803

View attachment 436805

Not a bad idea but probably not as precise as a block. Digging on you YouTube I turned up a guys videos of his model C 1694 and he had the original taper attachment so I grabbed some screen shots.

View attachment 436806

View attachment 436807

My top pulley measures 8.5” diameter with 1” bore.I remembered yesterday that I’m missing the larger 3 groove top input pulley and was wondering if someone would be kind enough to measure theirs so I can start looking for one? I think I can find a place to make one.

Really like that back panel!Congratulations on your find. From what I can see, it looks complete and in pretty decent shape. Interesting history, too. I also have a 12c. It is a 1954. I did a restoration on this machine, and I’ve posted a few pictures of it after the restoration. If you’re interested, you can also find my restoration documented on the Practical Machinist forum (link below.)

I personally believe these are one of the best toolroom lathes of this size ever made. Best not to get me started on why as I could ramble on. Congratulations again on finding your machine.

https://www.practicalmachinist.com/forum/threads/pratt-whitney-12c-restoration-pictures.402002/

View attachment 433033 View attachment 433034 View attachment 433035 View attachment 433036