- Joined

- Oct 24, 2013

- Messages

- 481

For the standalone controller, I built my own using Arduino as the processor. I can send you the Arduino code for it. You will need to determine which size motor would best fit your particular table, probably a NEMA 17 or 23

www.homemodelenginemachinist.com

www.homemodelenginemachinist.com

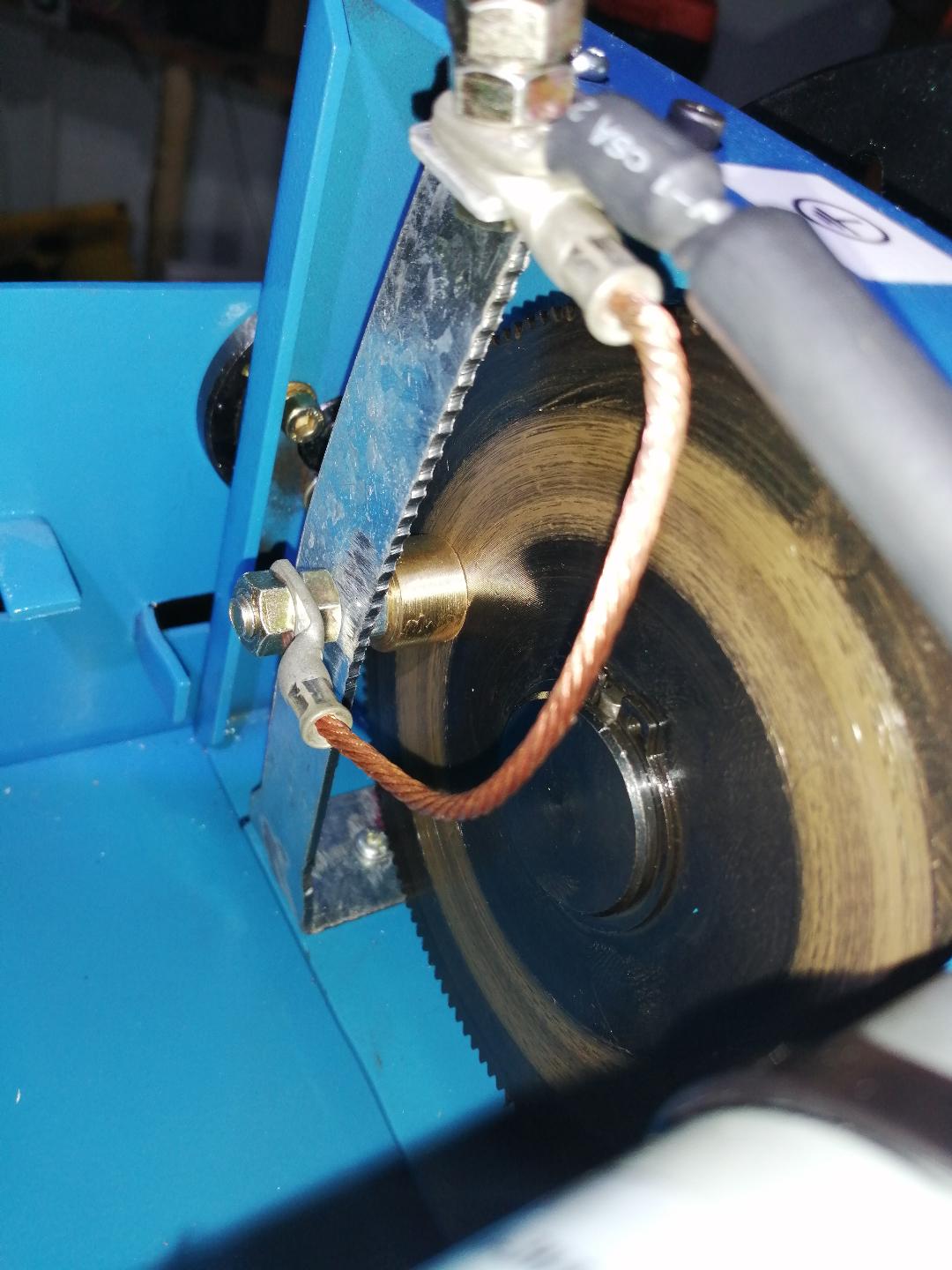

For my TIG welding rotary table (BTW my TIG welding talent is pretty atrocious), I bought this one on Amazon and did a few tweaks mainly beefing up the commutator arrangement for the work-clamp current flow, and replacing the speed potentiometer with a 10-turn pot for finer control

More stuff on it here:

forum.langmuirsystems.com

forum.langmuirsystems.com

Arduino Rotary Table for Dummies

Ive had a few people tell me that they like the project (http://www.homemodelenginemachinist.com/showthread.php?t=25783) but dont feel comfortable with the electronics. Ive been playing around to simplify it down to where I feel anyone who wants to could comfortably build the controller. With...

www.homemodelenginemachinist.com

www.homemodelenginemachinist.com

For my TIG welding rotary table (BTW my TIG welding talent is pretty atrocious), I bought this one on Amazon and did a few tweaks mainly beefing up the commutator arrangement for the work-clamp current flow, and replacing the speed potentiometer with a 10-turn pot for finer control

More stuff on it here:

Cletus' Crossfire Build n Mods

Oh yes, he has good videos. Also, I look at this and weep!

forum.langmuirsystems.com

forum.langmuirsystems.com

Last edited:

Serviced and re-calibrated my CNC Mini-Mill today. Here’s the second pass making a bolt-circle in a test coupon (1/4" Drill)

Serviced and re-calibrated my CNC Mini-Mill today. Here’s the second pass making a bolt-circle in a test coupon (1/4" Drill)