-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pretty sure I need a mill part 2 cleanup

- Thread starter DeadGuyAle

- Start date

- Joined

- Mar 22, 2022

- Messages

- 341

- Joined

- Mar 22, 2022

- Messages

- 341

- Joined

- Mar 22, 2022

- Messages

- 341

- Joined

- Mar 3, 2020

- Messages

- 506

DeadGuy, thanks for the step-by-step on disassembly.

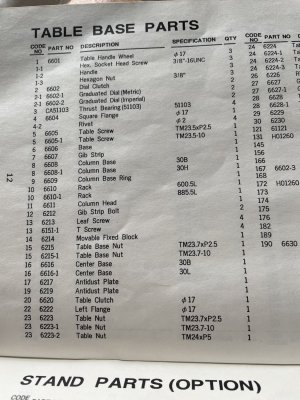

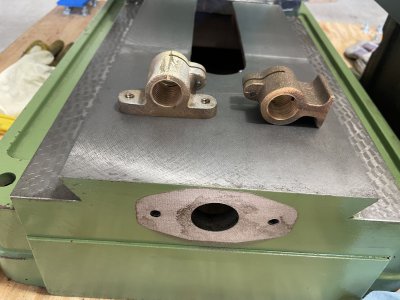

does the x axis adjustable leadscrew nut have a part number on it? Your photos clearly show the nut.

Grizzly part# in my on manual calls it the Longitudinal leadscrew nut pt#1005613.

I think I have adjusted all the backlash out of mine, (4mm allan with long extension) so I’ll be needing one in future.

there seems to be a couple different ones, (bronze & cast iron) so want to have one before disassembly if possible.

i have cheap igaging DRO on mine, so not a problem yet.

like i said my machine is a Grizzly G1006/1007, but appears identical to yours.

does the x axis adjustable leadscrew nut have a part number on it? Your photos clearly show the nut.

Grizzly part# in my on manual calls it the Longitudinal leadscrew nut pt#1005613.

I think I have adjusted all the backlash out of mine, (4mm allan with long extension) so I’ll be needing one in future.

there seems to be a couple different ones, (bronze & cast iron) so want to have one before disassembly if possible.

i have cheap igaging DRO on mine, so not a problem yet.

like i said my machine is a Grizzly G1006/1007, but appears identical to yours.

- Joined

- Mar 22, 2022

- Messages

- 341

Pretty sure it’s the same as the G1006/1007.DeadGuy, thanks for the step-by-step on disassembly.

does the x axis adjustable leadscrew nut have a part number on it? Your photos clearly show the nut.

Grizzly part# in my on manual calls it the Longitudinal leadscrew nut pt#1005613.

I think I have adjusted all the backlash out of mine, (4mm allan with long extension) so I’ll be needing one in future.

there seems to be a couple different ones, (bronze & cast iron) so want to have one before disassembly if possible.

i have cheap igaging DRO on mine, so not a problem yet.

like i said my machine is a Grizzly G1006/1007, but appears identical to yours.

The manual that came with it shows part #23 with multiple options also.

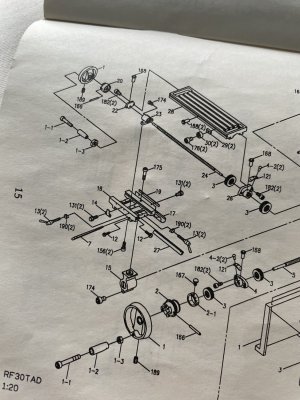

I’ll check things out closer this evening when I pull the saddle off and get the dimensions

Attachments

- Joined

- Mar 3, 2020

- Messages

- 506

This is the very basic DRO my machine has. Works great. Although my lathe does not have DRO, I can’t imagine running a mill without one.

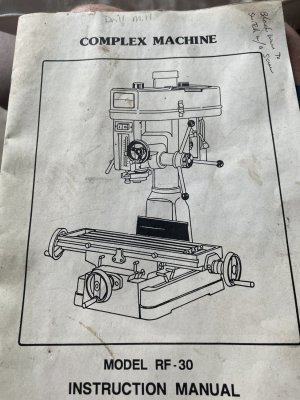

i have the same manual, also available on line.

these are robust machines, and they produce very accurate parts.

cheers

i have the same manual, also available on line.

these are robust machines, and they produce very accurate parts.

cheers

Attachments

- Joined

- Mar 22, 2022

- Messages

- 341

- Joined

- Mar 22, 2022

- Messages

- 341