Thank you Nogoingback I am 71 and with the lock down and a lot of time on my hands I just have to keep busy.

Lets make some timing gears next.

The blanks are cut out and ready for their teeth.

This is the setup I used for the 36 tooth gear.

I am using M1 metric cutters as that is the smallest tooth size I have.

This is the 18 tooth gear that mounts on the crank shaft.

Gears all done except for boring out the ID.

Don't they look nice?

Sure they do but they won't work on this engine because when I bore out the ID of the small gear there is not enough material left for the set screw.

I remember telling my self that these gears would have to be larger because the crankshaft is larger but I guess I had a senior moment. So now I am kind of upset with my self so I decided to make them 22 and 44 teeth so I was sure to have enough material left. I cut out the new blanks and mounted the 44 blank first then I set about setting up the rotary table.

Now I have made 5 dividing plates for my rotary table with three hole patterns on each one that's fifteen different hole spacings but not one of them will work for the gears I wanted to make.

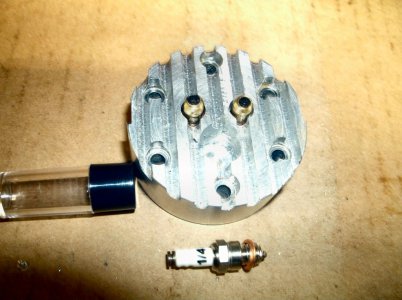

I ended up cutting the blanks down for 20 and 40 tooth gears and made sure the 20 tooth gear had plenty meat for the set screw so here they are.

No the big gear does not go on the crank shaft I just stuck it there to take the picture.

They did turn out nice though.

Thanks for looking

Ray