-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steady Rest

- Thread starter woodchucker

- Start date

- Joined

- Nov 25, 2015

- Messages

- 8,316

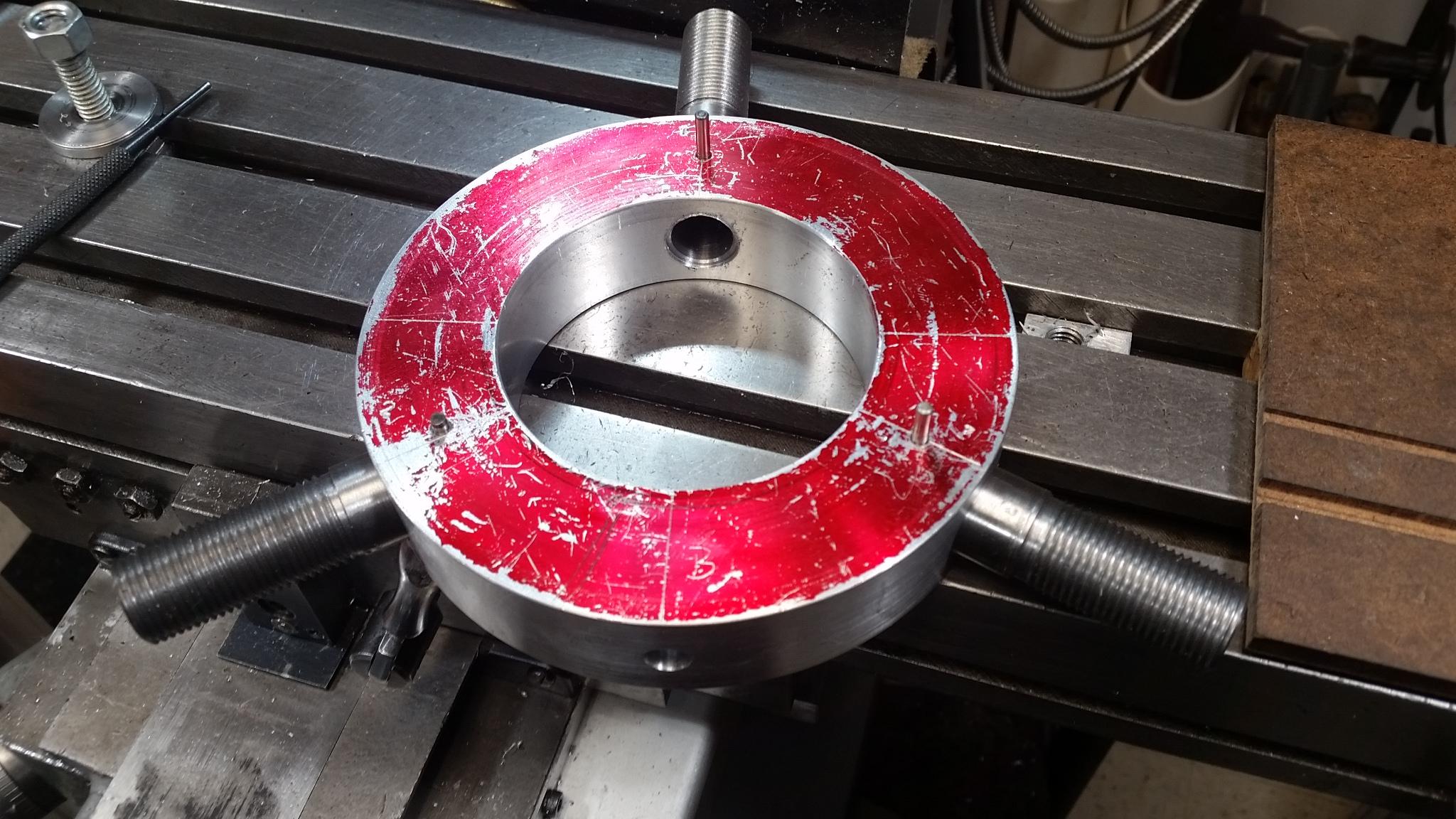

No, I'll counterbore it. , I'll probably use an allen socket cap screw, I am allowing myself room to remachine the bore of the ring if I ever need more space. I could either bandsaw it, or put it on a plate, clamp it down and turn it.. or clamp it to the mill bed and bore it.

I originally thought I would make it larger before I did the fingers, after looking, I though it could be bigger, but after a while I thought if I have a piece bigger than 3" or 3.5 I need a bigger lathe... damn, I already know I want a bigger lathe..

I have seen steady rests built heavier than this, and I have seen others way lighter than this. I don't know if I will get what I want from this, but I hope so.

I originally thought I would make it larger before I did the fingers, after looking, I though it could be bigger, but after a while I thought if I have a piece bigger than 3" or 3.5 I need a bigger lathe... damn, I already know I want a bigger lathe..

I have seen steady rests built heavier than this, and I have seen others way lighter than this. I don't know if I will get what I want from this, but I hope so.

- Joined

- Feb 25, 2021

- Messages

- 3,130

I may have said this already-but I need to get a steady and follow rest for the 25x50 Monarch. For the steady I mai just make a new base for some random large steadyrest. Or fab something from scratach s is lukely for the follow rest. Either way, I’ll be interested in how your’s turns out.

- Joined

- Nov 25, 2015

- Messages

- 8,316

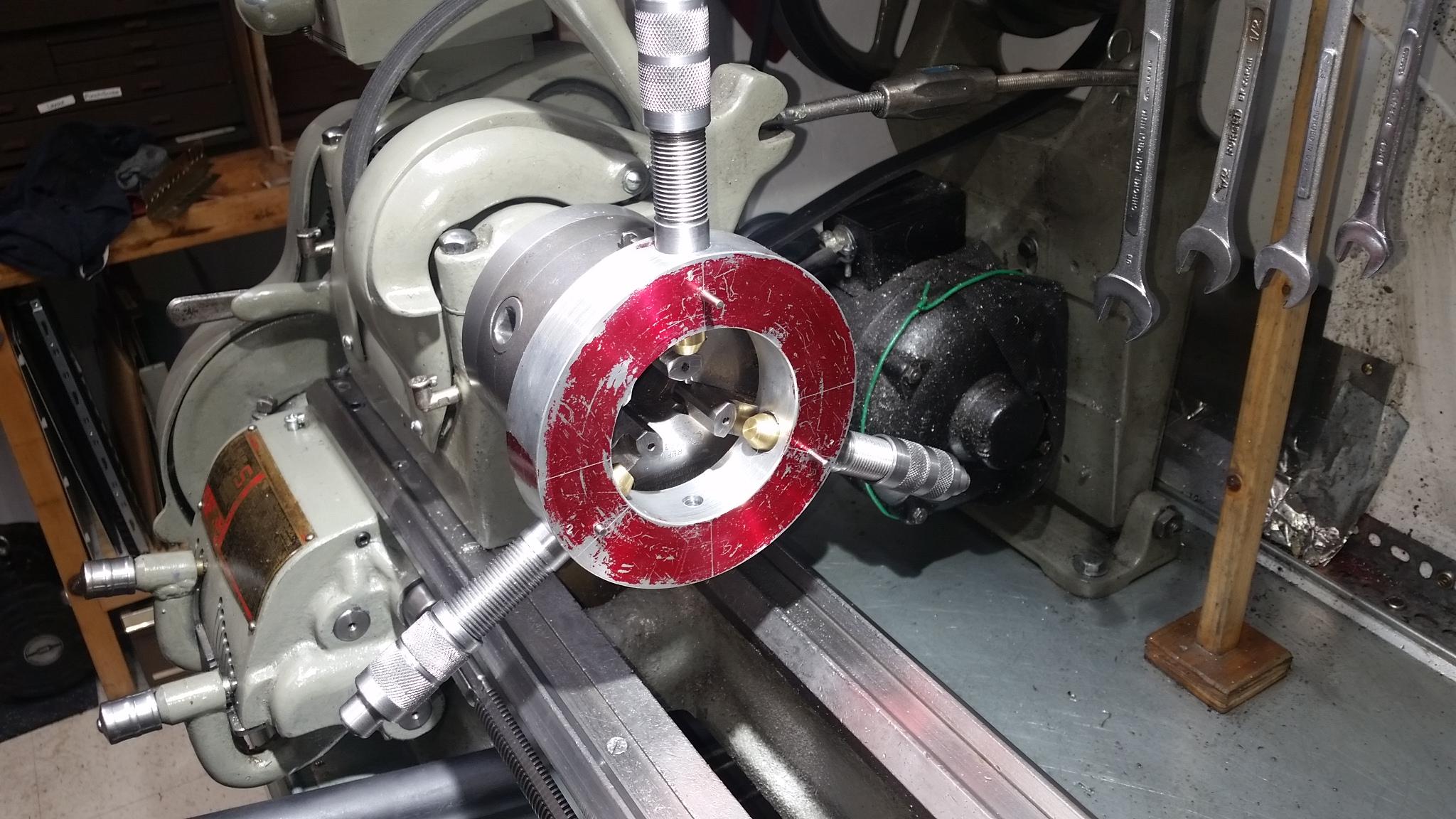

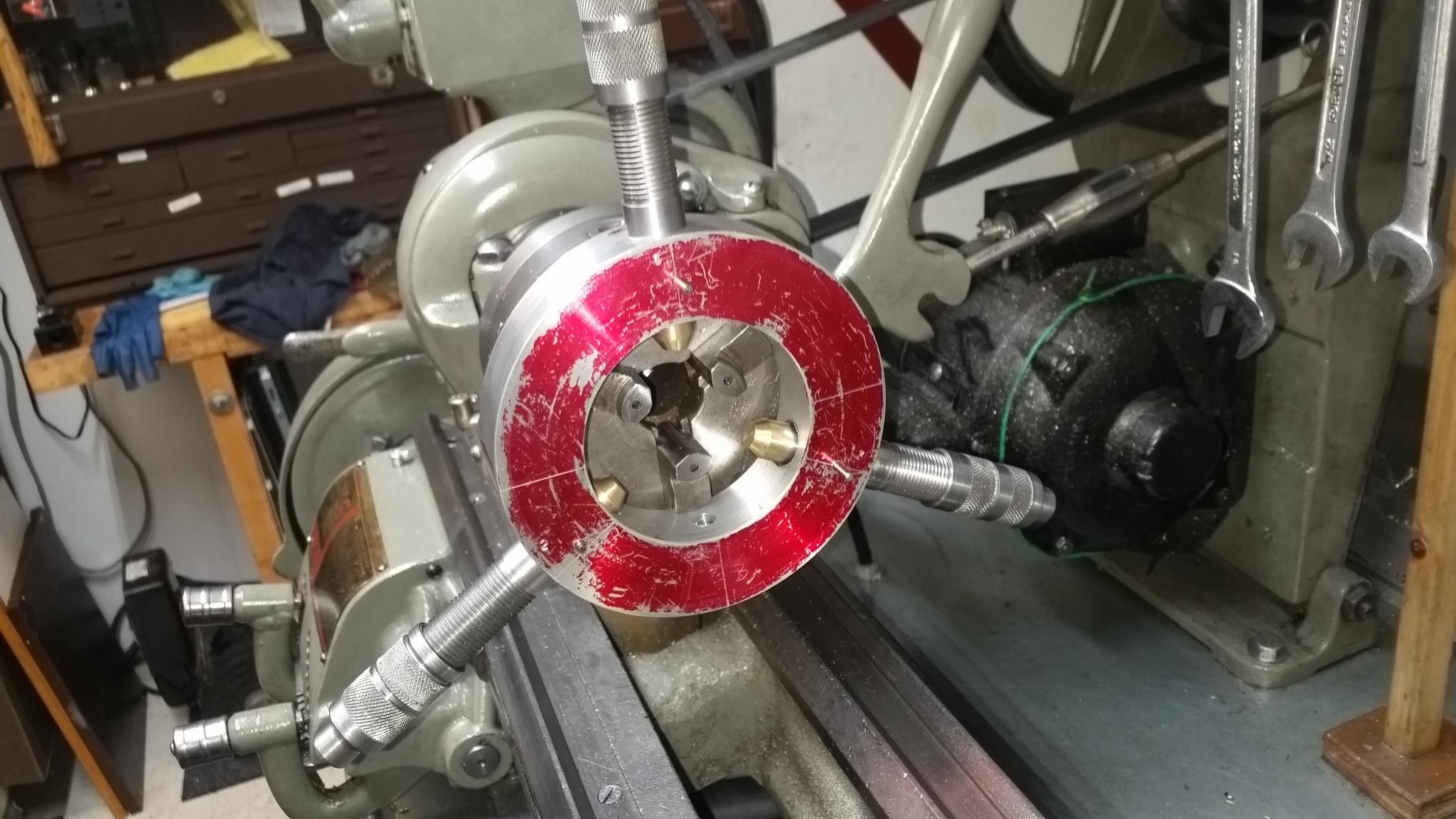

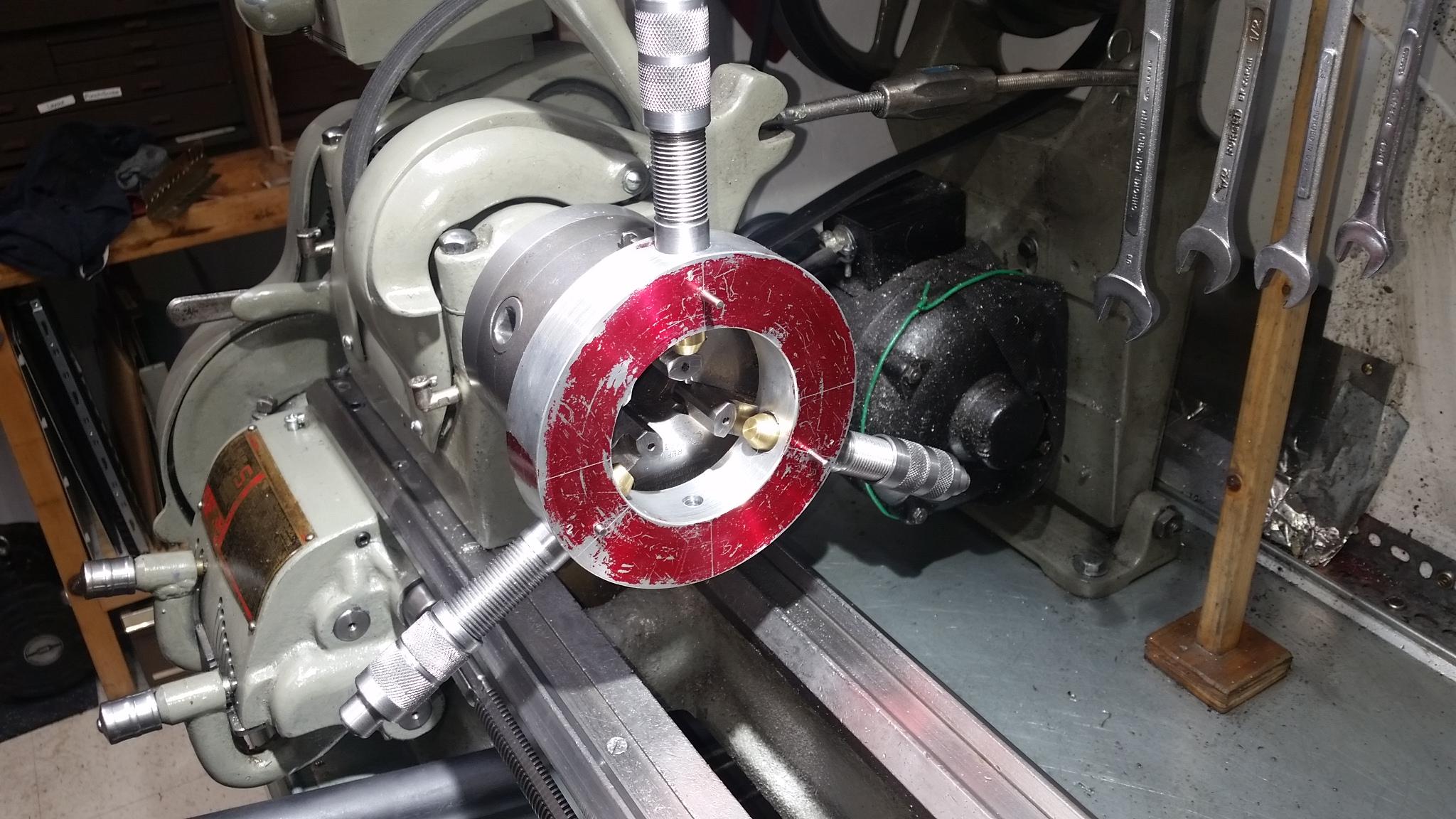

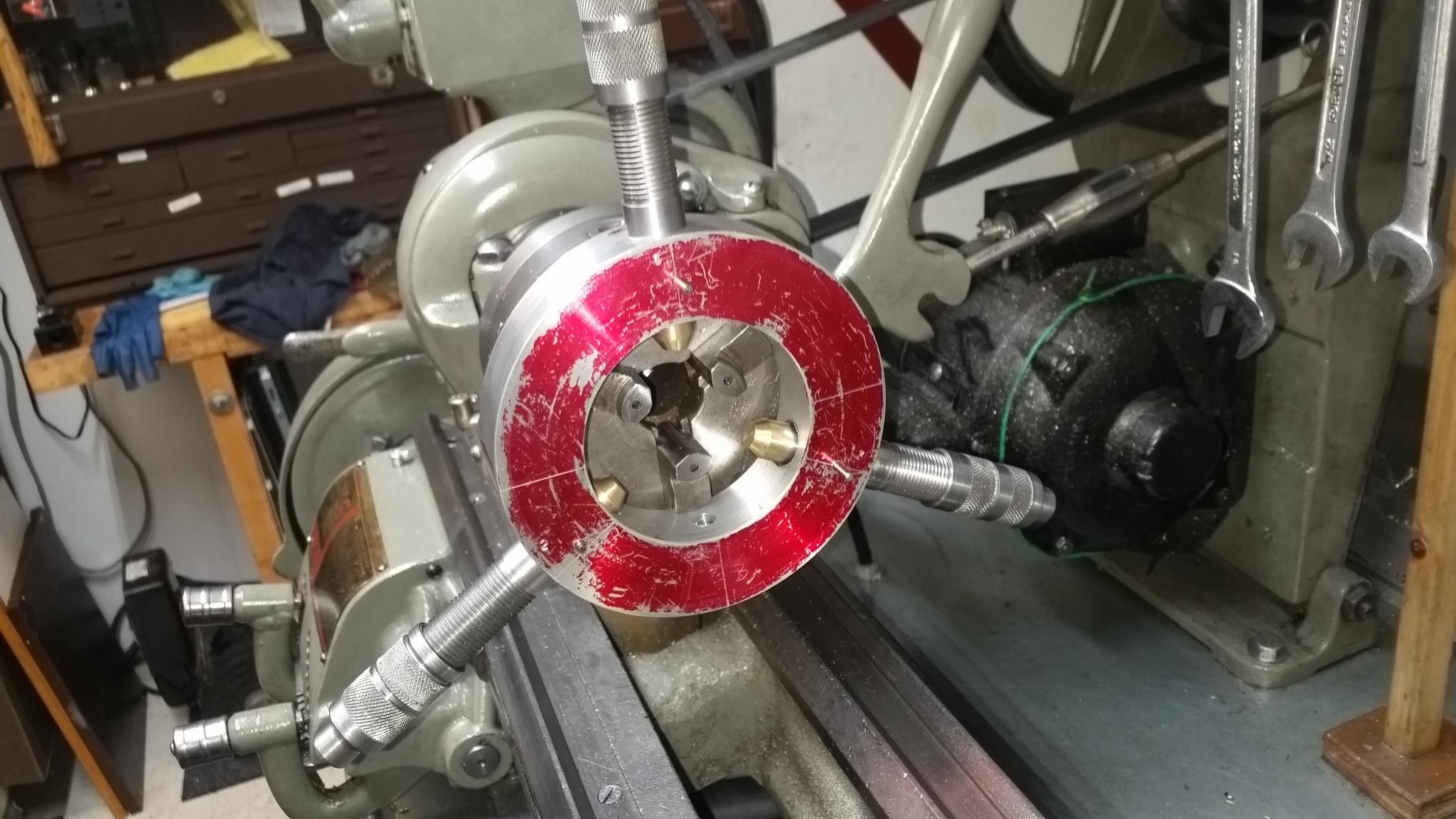

got a little more work done. drilled the dowel pin and locking knobs , as well as the bottoms screw.

I am a little confused, I am using numbers and plans provided , I don't fully understand the double screws, LH and RH do move the fingers. These seem like they would have worked with one screw, not 2. Oh well, live and learn. I really won't know until I finish it, if I am right or wrong. I have to run a groove down each finger for the locking screw, and also put the pin in the outer screw nut, and inner screw. Then work the timing out.

Just thinking out loud.. Time will tell.

I am a little confused, I am using numbers and plans provided , I don't fully understand the double screws, LH and RH do move the fingers. These seem like they would have worked with one screw, not 2. Oh well, live and learn. I really won't know until I finish it, if I am right or wrong. I have to run a groove down each finger for the locking screw, and also put the pin in the outer screw nut, and inner screw. Then work the timing out.

Just thinking out loud.. Time will tell.

Last edited:

- Joined

- Nov 25, 2015

- Messages

- 8,316

Grooved the fingers, pinned the screw to the cap. Having thoughts of upping the 1/8 dowel pins for the sleeves, to 3/16. I'm worried that the 1/8 might rip through the Aluminum 6061... It might just be nothing, but thinking the larger bearing surface will resist it better. Also thinking that I have too much screw. I used Mark's sizes, but they appear to be too much screw.

- Joined

- Mar 26, 2018

- Messages

- 8,407

I really like your lathe!This started without plans. Then I realized I better get some set up. I can't just wing it like others. I had an idea in my head to use this chunk of Aluminum, after cutting it, is when I realized that I need some idea of sizes of things.. Probably it would have been better to start that way. I needed a little more meat on the thickness to follow the plans. The plans were by Mark Frazier, he translated some SB sizes .. They seem too beefy for a SB9 in my opinion.

The pics are here on

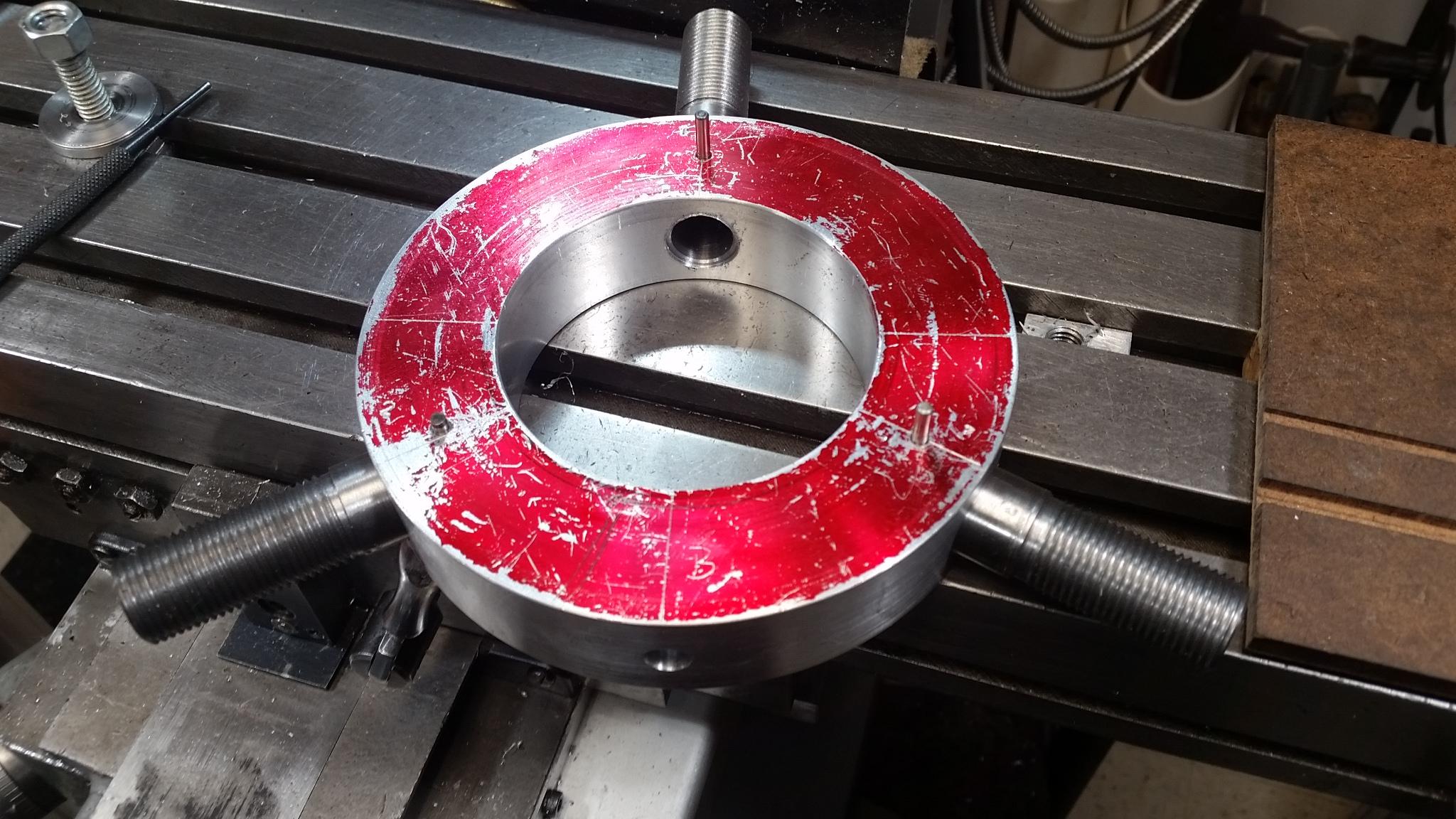

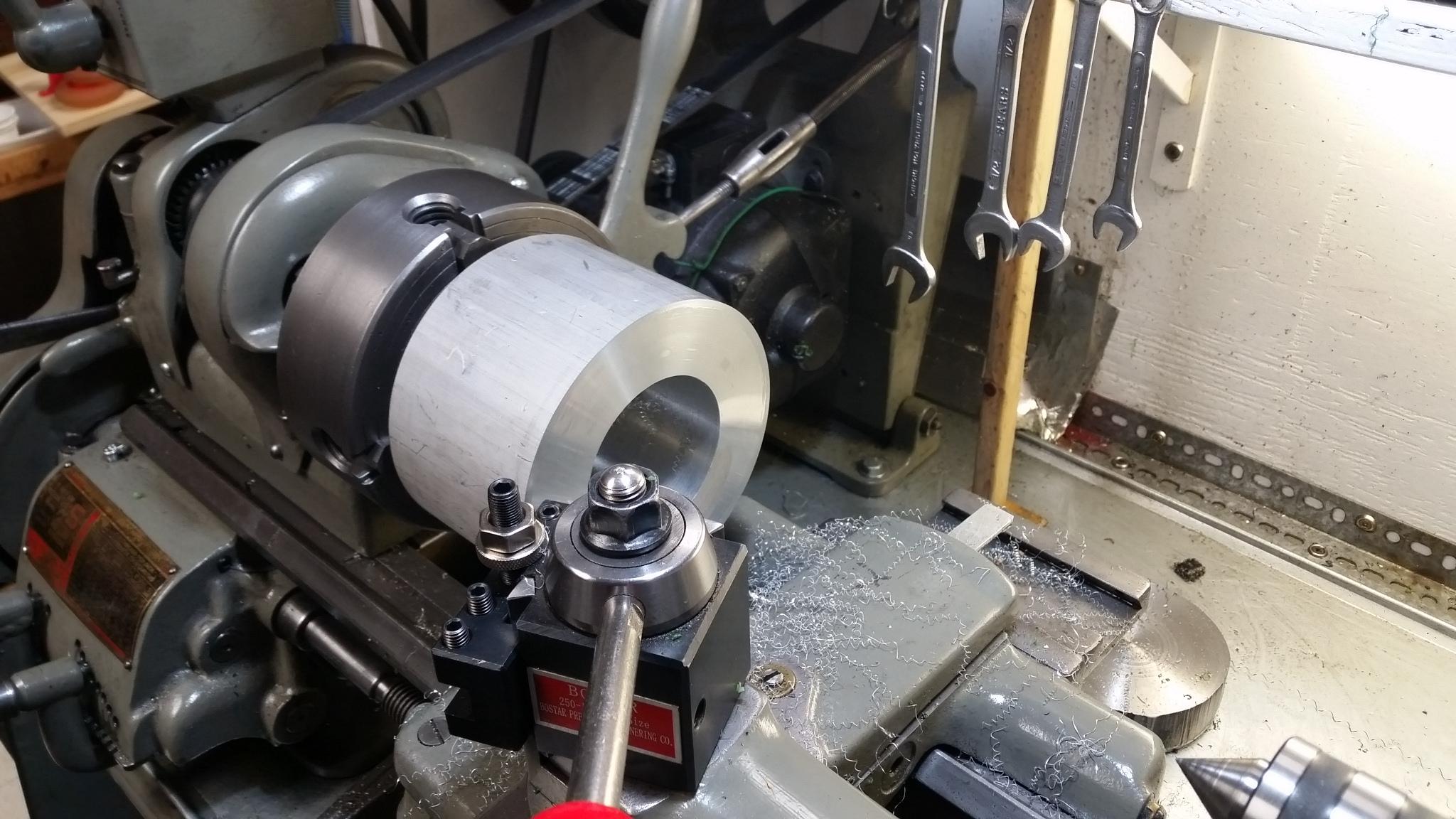

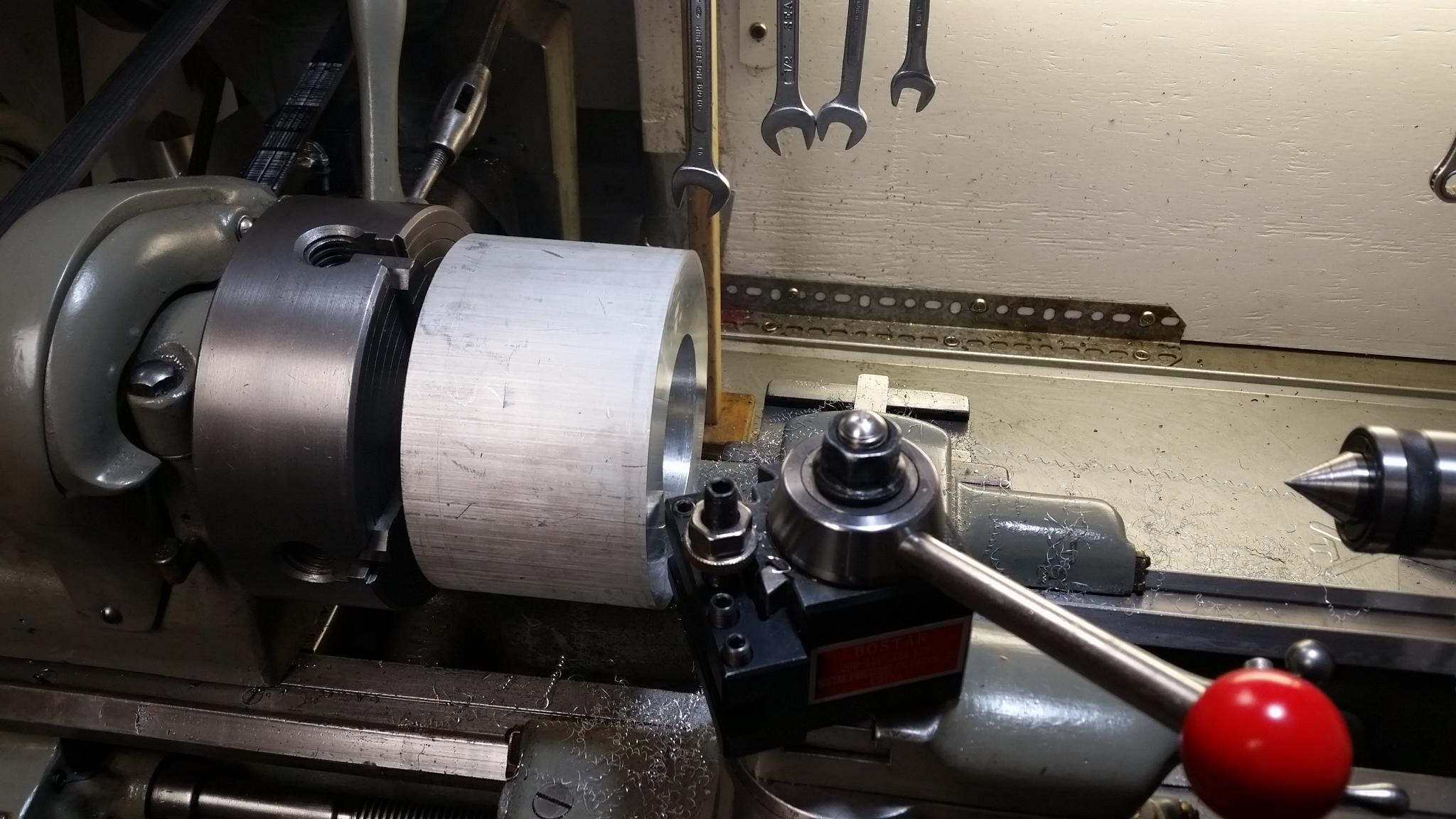

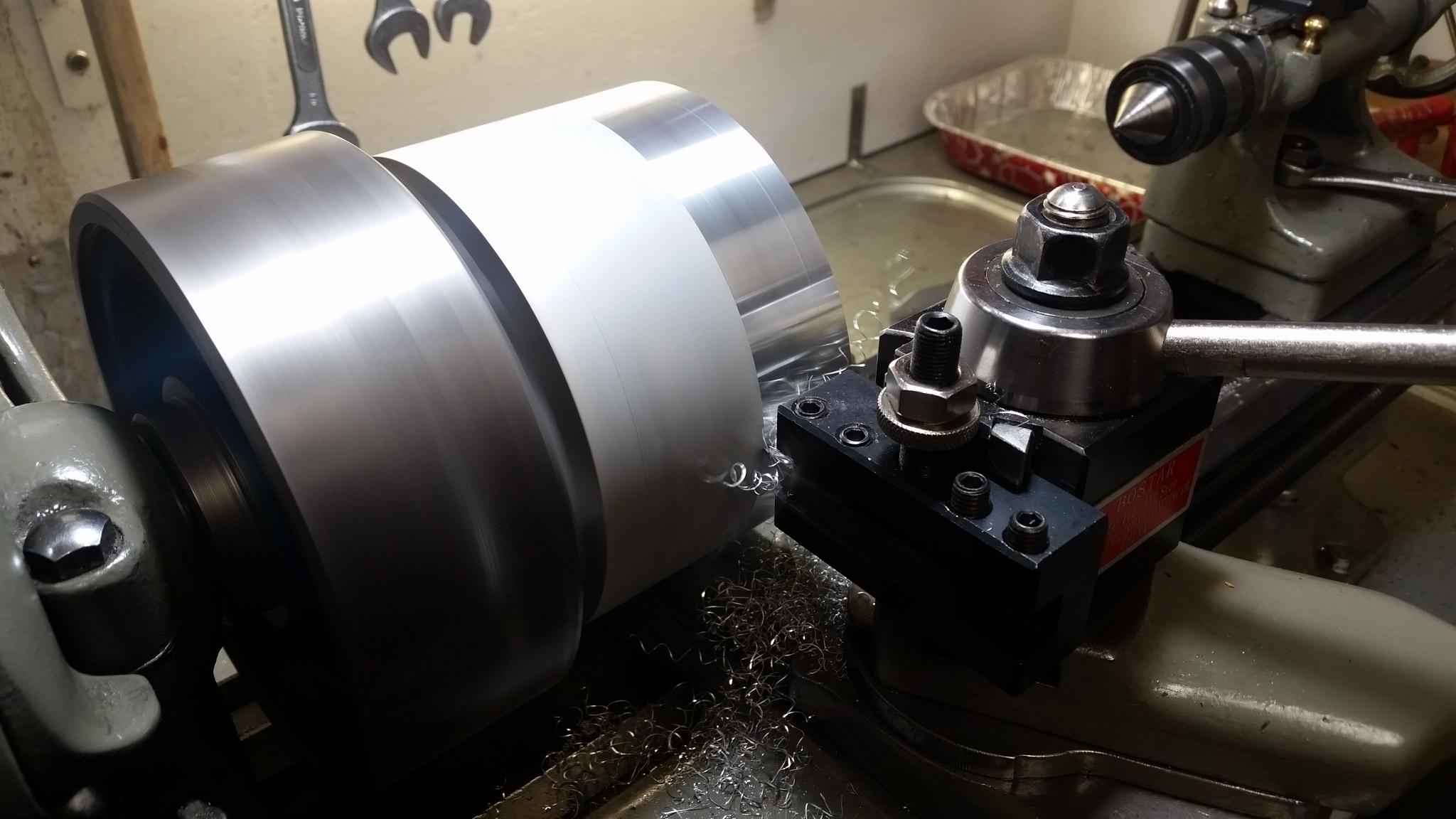

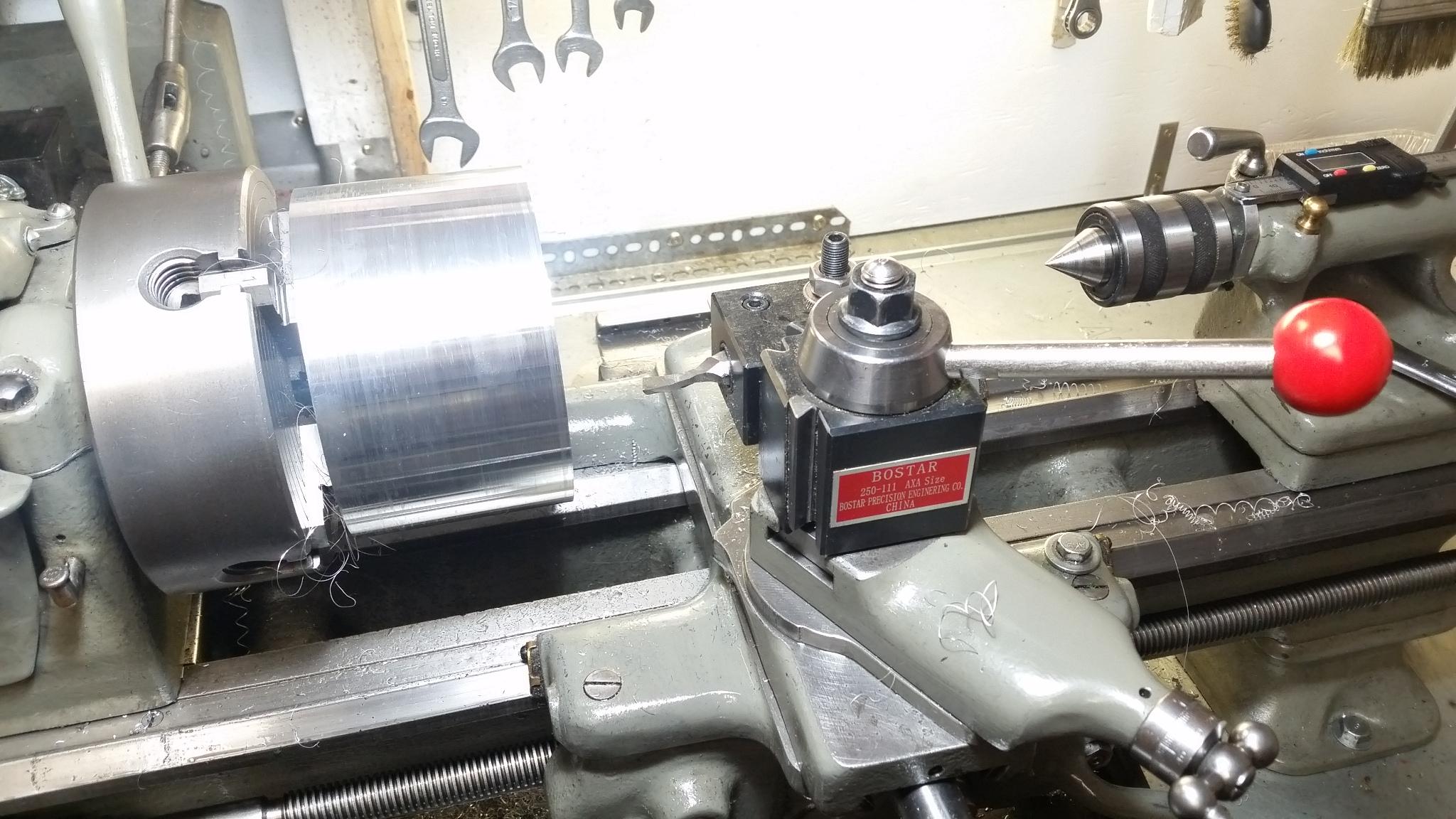

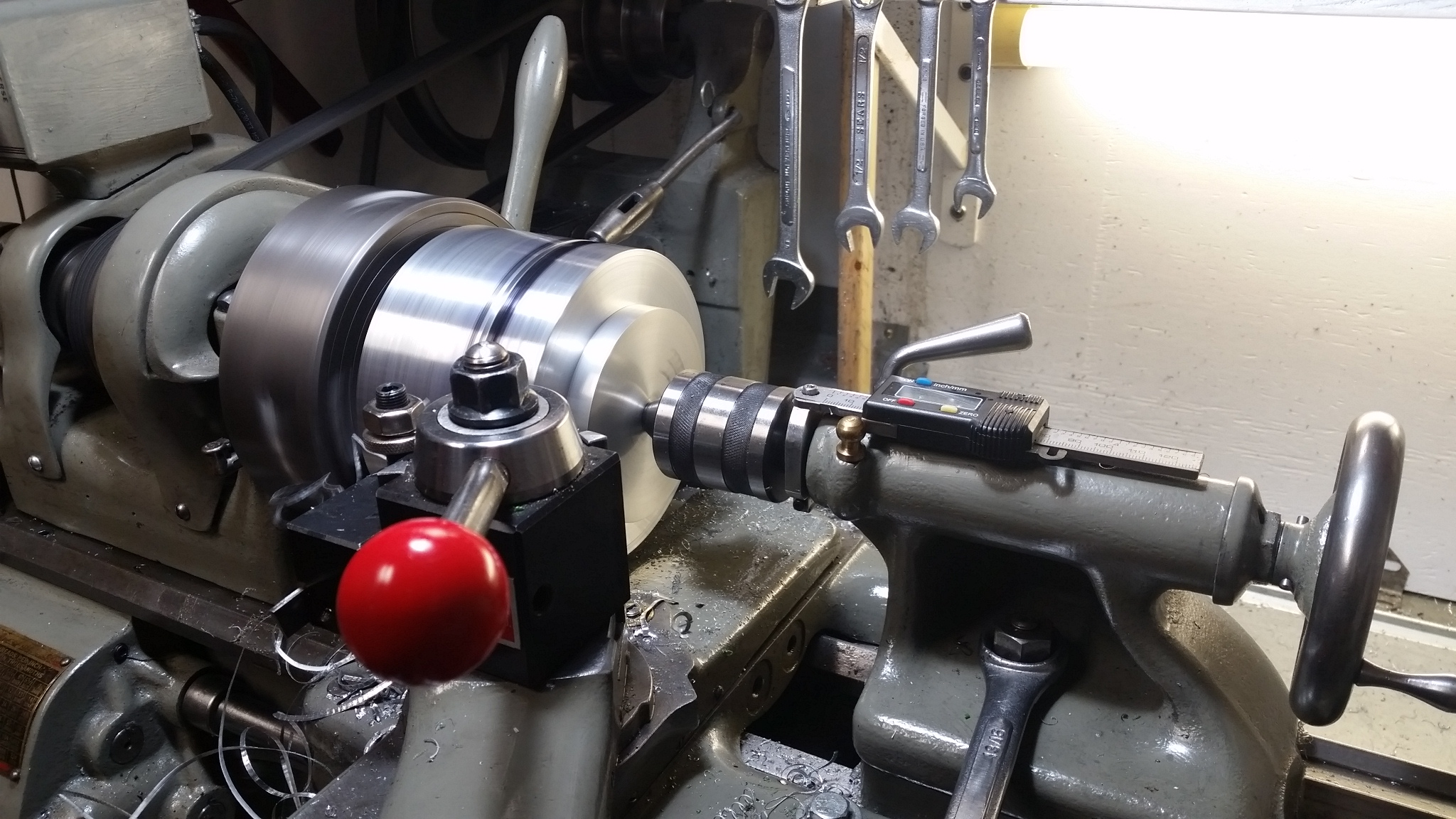

Facing the blank

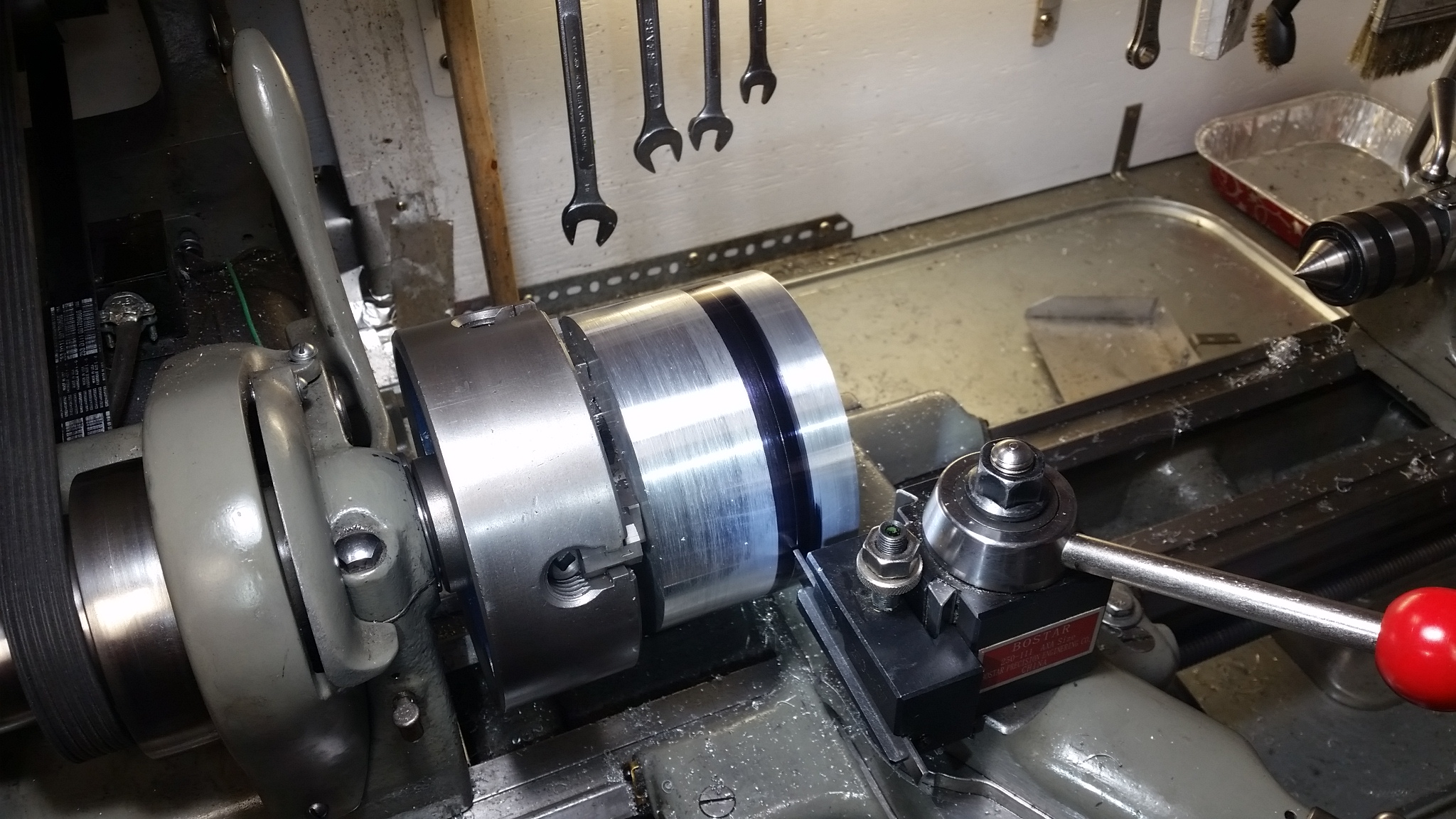

Turning it.

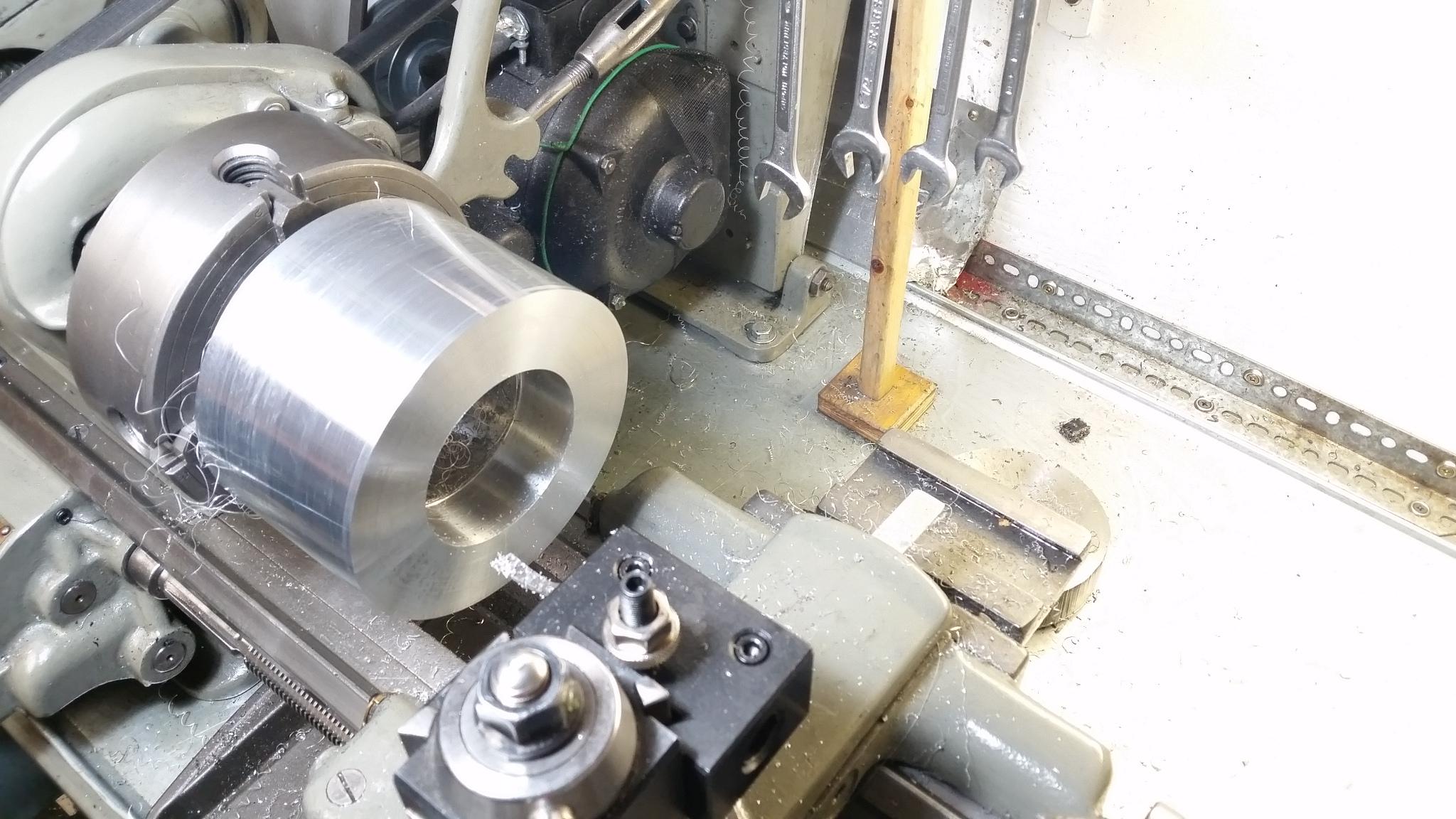

Begining to bore out the hole larger.

Parting it off

This was the first time I power parted. I normally always hand feed on parting. But this was going to be a lot of parting. I set up for a pretty high feed rate, and it was great. It spewed chips off as I hoped it would. I am now using power parting more.

I'm going to avoid using the pics on HM because of image size. Let's see how this works.

Did you restore it or was it like that when you bought it?

Or, are you the original owner?

- Joined

- Nov 25, 2015

- Messages

- 8,316

hmmmm, see this... this is how I got it for $250, no tooling, no nothing.I really like your lathe!

Did you restore it or was it like that when you bought it?

Or, are you the original owner?

And thank you.

- Joined

- Nov 25, 2015

- Messages

- 8,316

Well, I couldn't let it rest today. It was bothering me. I took another look and lopped off an an 3/4 to 7/8 if an inch off the fingers themselves.

Then I put flats on the brass ends so I can tighten them or remove them when I put blue loctite on.

Things are starting to come together. Next job is to pocket the area where the hinge will go. I'll inset some aluminum block in there, epoxy and pin it.

Then I put flats on the brass ends so I can tighten them or remove them when I put blue loctite on.

Things are starting to come together. Next job is to pocket the area where the hinge will go. I'll inset some aluminum block in there, epoxy and pin it.

- Joined

- Nov 25, 2015

- Messages

- 8,316

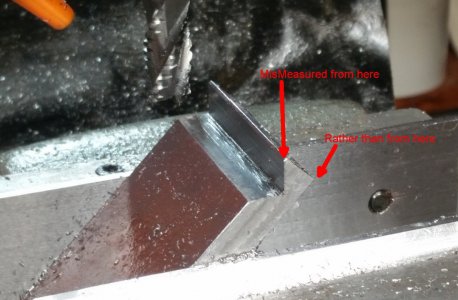

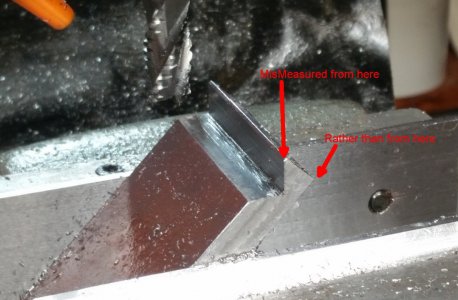

well I keep making beginner mistakes. I went to make the platform that sits on the ways, squared up a piece, measured, needed .375 in from the end for the 90 degree way. the .375 was the mid point. And went about making the beginner mistake. Mounted the stock in at 45, raised the knee until it touched the top of the piece , moved the quill to the back and raised the knee .375... DOH... Did you see the error?

Sorry for the lousy pics, my camera keeps focusing on the wrong thing, even though I give it the focal point, it somehow is changing it as I am shooting. Only if I mount my phone on a tripod does it stop doing that.

Sorry for the lousy pics, my camera keeps focusing on the wrong thing, even though I give it the focal point, it somehow is changing it as I am shooting. Only if I mount my phone on a tripod does it stop doing that.

- Joined

- Mar 23, 2022

- Messages

- 25

Very nice work on that lathe!!