-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steady Rest

- Thread starter woodchucker

- Start date

- Joined

- Nov 25, 2015

- Messages

- 8,315

Thank you.Very nice work on that lathe!!

Welcome to HM, we are a pretty friendly bunch... Feel free to jump in...

When you ask for an opinion, you will get a hundred different opinions.. It's up to you to figure out which ones fit.

You will find that there ARE experts in certain areas, and they go over and beyond to help you. You just need to provide good info and pics to help them help you.

- Joined

- Mar 23, 2022

- Messages

- 25

Thanks Woodchucker! I'm just getting started and found this site. I'm sure it will be an invaluable source of info for me! Most of what I see here is well beyond me.

- Joined

- Nov 25, 2015

- Messages

- 8,315

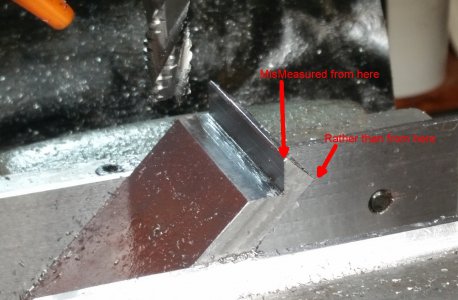

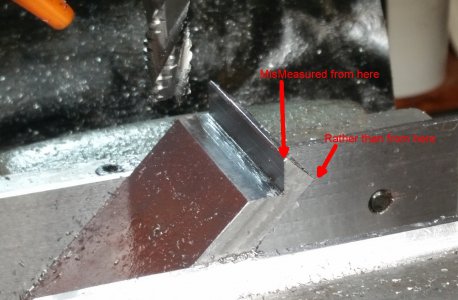

I left it. I look at it this way, I could re-do it so no one sees my mistake, or leave it , as an annoying reminder of what I did wrong so I don't forget (which I may anyway). This really doesn't harm anything, maybe it makes it a little weaker.. maybe.. I just shortened the piece so it fit.. I watched a youtuber show a method afterwards, but it was WRONG, and since the measurements were not shown, nobody caught it. They went through all these trig calcs, but only 2 values were needed and they solved the entire thing. I was amazed at how not one person commented on it.But looks like you were able to recover from it? Started again? Or where you able to fix the mistake in the same stock?

- Joined

- Nov 25, 2015

- Messages

- 8,315

- Joined

- Nov 25, 2015

- Messages

- 8,315

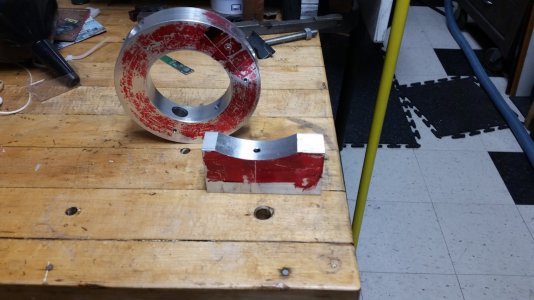

Time to start bringing this thread up to date. Most of the posts have gone to the what did you do in your shop today.

Got the hinge made, pinned it in as well as used JB Weld to keep it secure. It opens pretty nice. Just as I hoped. Used the rotary table to get the radius from the hinge pin.

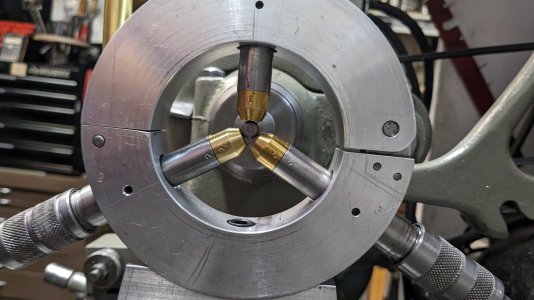

Used some brass coated steel for the securing screw, and then turned a brass nut with a long extension to reach over the ring.

This has just been replaced, so this is the original, and the reason it gets replaced is because I made a bad decision after coming back from vacation, and forgot that I needed to pin it, instead I placed a groove and lowered the height of the rest, so it needs redoing.

This is how much it shifted.

Started on the new blank. Got it squared, had a brain fart, didn't remember you can't fly cut mill scale...

Kept burning up the tool. face milled, and now cutting the new saddle pyramid.

Got the hinge made, pinned it in as well as used JB Weld to keep it secure. It opens pretty nice. Just as I hoped. Used the rotary table to get the radius from the hinge pin.

Used some brass coated steel for the securing screw, and then turned a brass nut with a long extension to reach over the ring.

This has just been replaced, so this is the original, and the reason it gets replaced is because I made a bad decision after coming back from vacation, and forgot that I needed to pin it, instead I placed a groove and lowered the height of the rest, so it needs redoing.

This is how much it shifted.

Started on the new blank. Got it squared, had a brain fart, didn't remember you can't fly cut mill scale...

Kept burning up the tool. face milled, and now cutting the new saddle pyramid.

- Joined

- Nov 25, 2015

- Messages

- 8,315

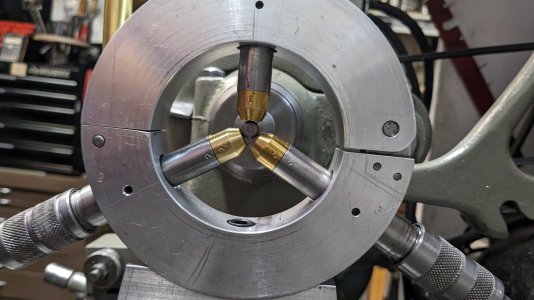

got some more done today.

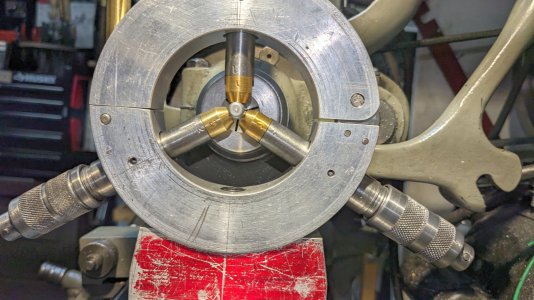

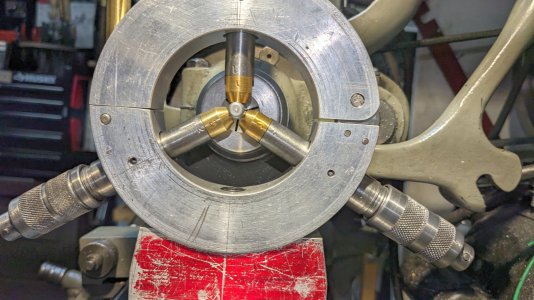

New plate roughed out the other day, today, finished the plate

Brought it back to center

Old plate and new. The new plate has some space between the groove I put in. I want it to pull down, and not bottom out.

Rather than use a squared off endmill, I used one of the many ball nose I have. Does the same thing.

Was going to drill and tap the ring to the base, but my scared German Shedder is at my feet. The thunder terrifies him. What a baby... and I wouldn't have him any other way... he's a gentle giant.

and I wouldn't have him any other way... he's a gentle giant.

New plate roughed out the other day, today, finished the plate

Brought it back to center

Old plate and new. The new plate has some space between the groove I put in. I want it to pull down, and not bottom out.

Rather than use a squared off endmill, I used one of the many ball nose I have. Does the same thing.

Was going to drill and tap the ring to the base, but my scared German Shedder is at my feet. The thunder terrifies him. What a baby...

- Joined

- Nov 25, 2015

- Messages

- 8,315

Todays work was to clean up the work, deburr, assemble..

I may need to blacken the metal to prevent rust, especially on the foot and clamp.

The little pins in the zip lock are for the opposite side of the locking screws. it prevents the screw holders from coming out if you remove the locking screw, it holds it in place.

Two more things to do, make the clamp for the ways, and the nut for the clamp. Started roughing the clamp..

Would like to finish this tomorrow, so I can work on 2 other big projects.

I may need to blacken the metal to prevent rust, especially on the foot and clamp.

The little pins in the zip lock are for the opposite side of the locking screws. it prevents the screw holders from coming out if you remove the locking screw, it holds it in place.

Two more things to do, make the clamp for the ways, and the nut for the clamp. Started roughing the clamp..

Would like to finish this tomorrow, so I can work on 2 other big projects.

- Joined

- Nov 25, 2015

- Messages

- 8,315

Got the clamp done, I decided not to go the extra mile and make a nut that would be captured. For the few times I will need this, it isn't necessary. I had a flange nut with teeth, and that seems to grab the clamp on it's own.

videos will have to be loaded to youtube, our system won't handle it.

Be back with videos shortly.

videos will have to be loaded to youtube, our system won't handle it.

Be back with videos shortly.

- Joined

- Nov 25, 2015

- Messages

- 8,315

Don't seem to be able to get the video to show the splash page.. but it works.