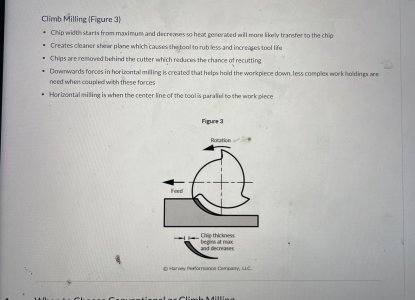

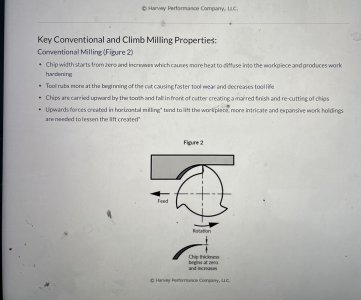

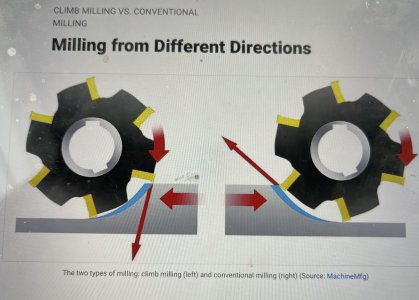

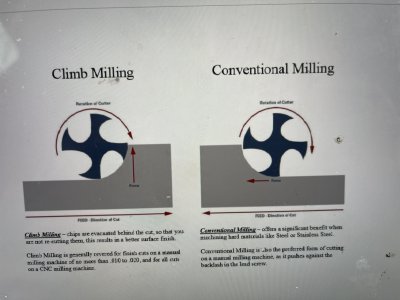

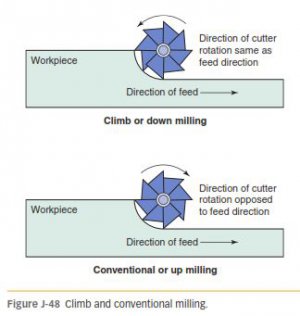

The direction of cut is the direction that the tool moves relative to the work, this does not change if the tool moves or the work moves.I think one of the confusing issues is what is the direction of feed. The Harvey paper shows the direction of feed as the direction the cutter is moving relative to the work. When we feed with a mill, the cutter is stationary and we feed the work into it. The two are opposites. It doesn't help that in some of the illustrations, it isn't clear which is being referred to.

Let me explain this again. If someone finds this terribly difficult to understand then they will probably never get the principle.