- Joined

- Jan 25, 2015

- Messages

- 2,558

JPMACG generously donated a Dual 1229Q turntable to me for the cost of shipping:

Problem is, it's been sitting around awhile so it's going to have the usual age related items (dried out rubber bits, old stiff grease, delicate dried out plastics, etc) and the tone arm has taken a "smack" in it's past. Looks like:

Yeah, that's pretty bad! JP didn't say what happened to it, but it's suspiciously dented in about the same places if you mistakenly dropped the platter on it...and this is one heavy platter. Heaviest I've ever held....I think it specs out somewhere around 6-7 lbs. That's heavy! Lots of flywheel effect there to keep the rumble, wow and flutter to a minimum.

To be clear, none of this is JP's fault, it's just what happens with old audio equipment that's been boxed up and left for long periods of time and I knew about the tone arm damage. Most of it is just wear and time, not neglect. Besides, "pay for shipping and it's yours"....can't complain about that price!

So, I get it on the stand and start going through it:

Turns out it's in worse shape than the Dual 1249 I bought on an ebay grab that looked pretty beat from the auction pictures. Allow me to elaborate:

Plug it in and give it a try. No platter drive. Spin it by hand and still no drive. Idler wheel looks ok visually:

No cracks and feels relatively "supple" so it's probably a little slippery or hardened just enough with age, or perhaps it's just shrunk overall in diameter with time and no longer makes sufficient contact. Dunno. Motor runs the idler fine with the platter off.

So that's going to be a replacement.

I may try a couple tricks (sandpaper, silicone spray to expand and soften, etc) to see if I can at least get it to drive the platter, mostly so I can tell if it's the wheel itself that's the problem or an adjustment. Although I don't see any capacity for adjustments.

The anti skate wheel is cracked, which appears to be a common issue for these things. Repair or 3d print another....I'll have to think about that one a bit.

Tone arm lift for multi is just plain jammed. Nothing seems to free it up. So I'll have to get down into the mechanism and see if it's a hardened rubber ring or not. Likely it is, so that will be another replacement.

Arm doesn't move, but there's no steurepimple (little rubber nib) at all so that seems to be a no brainer.

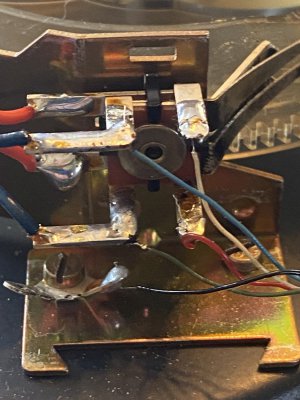

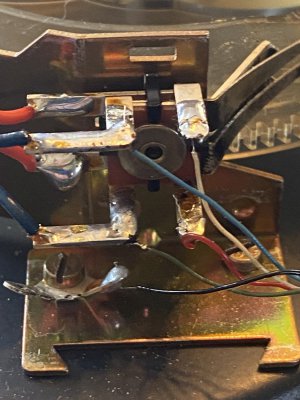

The arm itself is a different story. No way to fix the bend unless it's disassembled so a quick snap of the tone arm wire positions:

And then desolder. Then, the big dive:

Yeah, that's a drastic move and it will be a PITA to reassemble/readjust without factory jigs/tooling, but there's no choice with that arm bent the way it is:

It's try to fix it or toss it out and try to find another. Yeah, good luck with that....I'll try "fix it" first. Nothing to loose but a little of my time.

That pic is after using a screwdriver shank to straighten it out a little bit so you get the idea about how "out of whack" it is.

I don't think making another is an option. the tube is some of the thinnest aluminum I've seen so trying to machine another would be an exercise in frustration. If you try to bore something that thin, you usually just end up either crushing it or it just goes all out of whack when turning. No, I'm stuck with either fix or replace....

Next up is coming up with something to help reform the tube to a round shape and then into the v blocks to true it up. It shouldn't be too hard because that tube is super thin and super easy to bend. I actually had to be very careful just doing the initial straightening not to go too far. Now that it's apart, making a mandrel type arrangement to drive through it will be a doodle. But it's still going to be a delicate process as the tube is soooo thin.

If I do get it straight again, putting it all back together (properly) will also be a challenge....the service manual doesn't go this deep into disassembly.

I think the table is worth the effort though. A 1229Q isn't exactly "rare" or particularly valuable, but it's not that common either....

So,anyone think of a way to straighten that tube?

I'm thinking machine a "bullet'a few thou smalled than the ID and press it through. Then into the v blocks and true it up. Sound reasonable?

Problem is, it's been sitting around awhile so it's going to have the usual age related items (dried out rubber bits, old stiff grease, delicate dried out plastics, etc) and the tone arm has taken a "smack" in it's past. Looks like:

Yeah, that's pretty bad! JP didn't say what happened to it, but it's suspiciously dented in about the same places if you mistakenly dropped the platter on it...and this is one heavy platter. Heaviest I've ever held....I think it specs out somewhere around 6-7 lbs. That's heavy! Lots of flywheel effect there to keep the rumble, wow and flutter to a minimum.

To be clear, none of this is JP's fault, it's just what happens with old audio equipment that's been boxed up and left for long periods of time and I knew about the tone arm damage. Most of it is just wear and time, not neglect. Besides, "pay for shipping and it's yours"....can't complain about that price!

So, I get it on the stand and start going through it:

Turns out it's in worse shape than the Dual 1249 I bought on an ebay grab that looked pretty beat from the auction pictures. Allow me to elaborate:

Plug it in and give it a try. No platter drive. Spin it by hand and still no drive. Idler wheel looks ok visually:

No cracks and feels relatively "supple" so it's probably a little slippery or hardened just enough with age, or perhaps it's just shrunk overall in diameter with time and no longer makes sufficient contact. Dunno. Motor runs the idler fine with the platter off.

So that's going to be a replacement.

I may try a couple tricks (sandpaper, silicone spray to expand and soften, etc) to see if I can at least get it to drive the platter, mostly so I can tell if it's the wheel itself that's the problem or an adjustment. Although I don't see any capacity for adjustments.

The anti skate wheel is cracked, which appears to be a common issue for these things. Repair or 3d print another....I'll have to think about that one a bit.

Tone arm lift for multi is just plain jammed. Nothing seems to free it up. So I'll have to get down into the mechanism and see if it's a hardened rubber ring or not. Likely it is, so that will be another replacement.

Arm doesn't move, but there's no steurepimple (little rubber nib) at all so that seems to be a no brainer.

The arm itself is a different story. No way to fix the bend unless it's disassembled so a quick snap of the tone arm wire positions:

And then desolder. Then, the big dive:

Yeah, that's a drastic move and it will be a PITA to reassemble/readjust without factory jigs/tooling, but there's no choice with that arm bent the way it is:

It's try to fix it or toss it out and try to find another. Yeah, good luck with that....I'll try "fix it" first. Nothing to loose but a little of my time.

That pic is after using a screwdriver shank to straighten it out a little bit so you get the idea about how "out of whack" it is.

I don't think making another is an option. the tube is some of the thinnest aluminum I've seen so trying to machine another would be an exercise in frustration. If you try to bore something that thin, you usually just end up either crushing it or it just goes all out of whack when turning. No, I'm stuck with either fix or replace....

Next up is coming up with something to help reform the tube to a round shape and then into the v blocks to true it up. It shouldn't be too hard because that tube is super thin and super easy to bend. I actually had to be very careful just doing the initial straightening not to go too far. Now that it's apart, making a mandrel type arrangement to drive through it will be a doodle. But it's still going to be a delicate process as the tube is soooo thin.

If I do get it straight again, putting it all back together (properly) will also be a challenge....the service manual doesn't go this deep into disassembly.

I think the table is worth the effort though. A 1229Q isn't exactly "rare" or particularly valuable, but it's not that common either....

So,anyone think of a way to straighten that tube?

I'm thinking machine a "bullet'a few thou smalled than the ID and press it through. Then into the v blocks and true it up. Sound reasonable?

Last edited: