- Joined

- Jan 25, 2015

- Messages

- 2,558

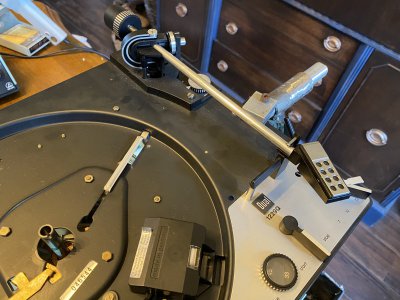

Thats a good lead, I’ll check in to it.I have seen thin wall carbon fiber tubing that is very stiff and very light weight. It is used by the the radio control model airplane hobby folks. I can ask around on one of the RC forums if you are interested.

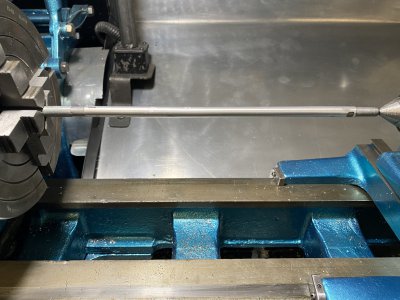

Right now, google is failing to find tubing that makes the id and od. If the od is good, the id is too small. If the id is good, the od is too big. Needs super thin walls…