- Joined

- Jun 11, 2019

- Messages

- 84

Great to see so many others with the Summits. I wasn't sure that there were many out there. One of the machine shops here in Jacksonville has a few and one really large one. Mine seems to be in pretty good condition and talking to the repair guy I have one of the better models that they made. I'm working on figuring out the fittings for the pump and hopefully I can get this thing put back together soon.

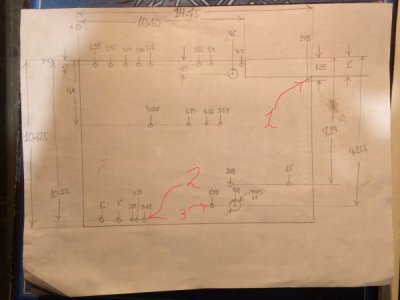

Zyox, I couldn't get a drip pan or dimensions from the manufacturer. Any chance you could get some measurements of yours? Outside dimensions and where all the drip holes are. Also, does your 19-4 have the oil distribution block like mine? Ronnie at Summit made it sound like that wasn't on all of them. I have an open port on mine and I'm not sure where that line is supposed to go.

Yes! It is, I enjoy seeing and sharing knowledge of these summits, they where a pretty spiffy lathe honestly! You don’t see Inch & MM threading on older lathes very often, usually you have to switch gears out for metric threads

And I can certainly make up a drawing of those drip plate dimensions!. The plate has some copper lines on the bottom that direct the oil a few places including the sight glass.. might take a bit of tinkering but it is 100% doable!

I believe mine also has that oil block! I shall take a picture of it when I get home~