Thanks Matt, I'll look him up.I vaguely remember Doc Nickel over on PM/ HSM adding an external pump and filter to his large lathe (Springfield?). Might be worth looking him up to see what he used.

Sent from my SM-G960U using Tapatalk

Thanks Matt, I'll look him up.I vaguely remember Doc Nickel over on PM/ HSM adding an external pump and filter to his large lathe (Springfield?). Might be worth looking him up to see what he used.

Nice seeing you put some love to this old girl! We have exactly the same lathe (model 19-4 size 19x60)

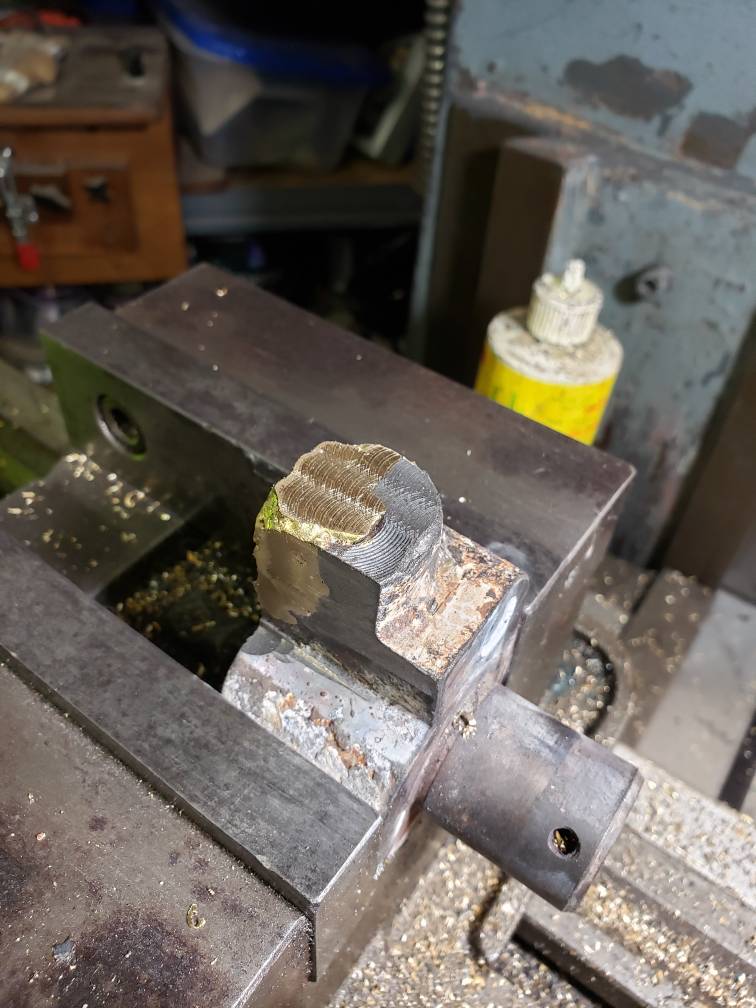

Believe it or not that lathe looks to be in pretty good shape, the one I have I bought from the machine shop I work at.. it had saw 20 years of daily hard use. Heavy turning and pushing in 2” drills with the carriage feed all day long.

The summit you have puts allot of lathes to shame, even a victor of the same size we have in our shop would stall the spindle and pop the feeds out doing the work our summit did.

But in the end 20 years of it left the forward clutch completely wore out and left every ball/needle bearing in the carriage toast as well as the worm gear for the X feed heavily worn.

I am currently in the process of resurrecting her just like you are doing.

I noticed this,.. are you missing the oil drip pan in the main drive/clutch compartment?

Sadly, we have 7 newer Summit machines (all 4 years old or so) and at least 3 of them have needed major repair work. Just as so many other things, made cheaply relative to their former selves.

It’s an unfortunate situation how the new manual machines are so poorly built... from what I have saw this is true for allot of brands. I only buy older manual machines. They are allot cheaper and the quality difference is night and day... that summit I have was built in Canada

Pretty sure the new ones are built in China

huh, I just figured they were Taiwan machines ... but could very well be China made based on what I have seen.

Our HBM-110 boring mill had a full spindle replacement. 22" lathe had a shaft and bearings replaced in the headstock. The two knee mills, I stopped counting the issues with those ... but the 16", 18" and 42" lathes have been pretty good so far.

Nice seeing you put some love to this old girl! We have exactly the same lathe (model 19-4 size 19x60)

Believe it or not that lathe looks to be in pretty good shape, the one I have I bought from the machine shop I work at.. it had saw 20 years of daily hard use. Heavy turning and pushing in 2” drills with the carriage feed all day long.

The summit you have puts allot of lathes to shame, even a victor of the same size we have in our shop would stall the spindle and pop the feeds out doing the work our summit did.

But in the end 20 years of it left the forward clutch completely wore out and left every ball/needle bearing in the carriage toast as well as the worm gear for the X feed heavily worn.

I am currently in the process of resurrecting her just like you are doing.

I noticed this,.. are you missing the oil drip pan in the main drive/clutch compartment?