- Joined

- Dec 18, 2022

- Messages

- 1,681

Its about feeds and speeds....Could you not just drive the rotary or dividing head off the hand crank shaft with a right angle drive?

Edit: you would still have to figure a method to index for each spline / tooth.

Its about feeds and speeds....Could you not just drive the rotary or dividing head off the hand crank shaft with a right angle drive?

Edit: you would still have to figure a method to index for each spline / tooth.

I would like to have a small shaper for just that reason. I have seen several ways to do internal splines, one of which is using a tool and pressing it in, I am still studying the internal spline puzzle though...Can you do internal splines with a dividing head on a milling machine? Do you need a shaper also?

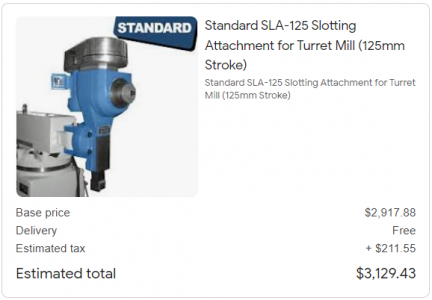

Yes a rotary broach is another way to do this and doesn't require a special machine, just an attachment for your lathe, you can make your own broach.... https://www.hemingwaykits.com/HK2570I'm no machinist so take this with a grain of salt.... Tooling is available, for small internal splines, using a Rotary Broach. Push through broaches are available and look like they work similarly to the way us hobbyists make keyways by broaching except with lots of slots cut at once. That way they can make involute "teeth". Dead end splines become a trickier game. Has anyone here made them? There are slotting heads available for the other end of a milling machine ram, I've never seen one in operation.

Personally, I've only made a few internal, thru, "splines" by indexing a keyway broach a few times. I used a brass hex bar and indexed to the outside of it. If I needed a dead end spline I'd fasten a thru spline to the shaft. Lots of ways to do that.

I had broached keyways with a 20 ton hydraulic press until I got a 3 ton ratcheting arbore press. Much faster with the arbore press but I've not done bigger keyways on it.

View attachment 485153

Can it make inside splines? Do you need to have mating male for the internal splines/involuted gear?Yes a rotary broach is another way to do this and doesn't require a special machine, just an attachment for your lathe, you can make your own broach.... https://www.hemingwaykits.com/HK2570

You would need to make the broach or male spline broach, cut it from tool steel then harden it...Can it make inside splines? Do you need to have mating male for the internal splines/involuted gear?

Watch this for better explanation.....Can it make inside splines? Do you need to have mating male for the internal splines/involuted gear?

CoolWatch this for better explanation.....