- Joined

- Mar 26, 2018

- Messages

- 8,407

That's the one I should have purchasedMine is the BS-2 Universal.

That's the one I should have purchasedMine is the BS-2 Universal.

Thanks a lot will watch them nowWatch these if you haven't already, good information and explanations...

Very interestingHere's one use for a rotary table. I used it to layout the degree lines for my lathe tool sharpening fixture.

Did you get it to connect to the x feed, or you need the bigger dividing head. The bs1 does not have the feed but I looked and you can theoretically rig a stepper motor at the handle of the bs1Mine is the BS-2 Universal.

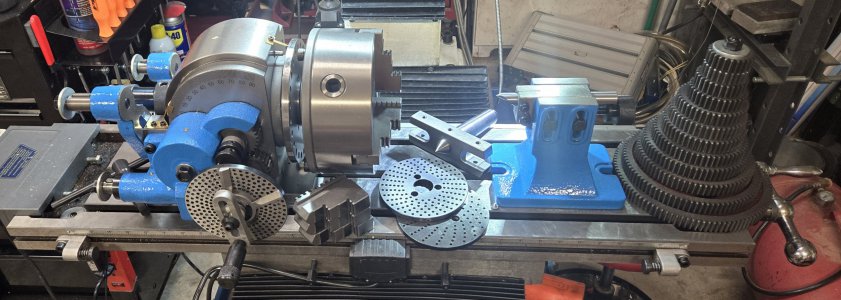

This is what I purchased. It is the universal. It will connect to the x-axis lead screw to cut helix, spiral and worm gears. I plan on moving my x-Axis power feed, which will require a ned power unit, to the right end of the table as it would be mounted on a knee mill. For scale you have the same mill table, 940, that is setting on my mills table.Did you get it to connect to the x feed, or you need the bigger dividing head. The bs1 does not have the feed but I looked and you can theoretically rig a stepper motor at the handle of the bs1

Super nice. Just I will beat the bs1 before committing 1kThis is what I purchased. It is the universal. It will connect to the x-axis lead screw to cut helix, spiral and worm gears. I plan on moving my x-Axis power feed, which will require a ned power unit, to the right end of the table as it would be mounted on a knee mill. For scale you have the same mill table, 940, that is setting on my mills table.

View attachment 485097

I considered the universal but figured I'd have my hands full with the semi-universal BS-1. I'll be watching your posts showing the spiral gears you make. I've made a couple of splines but have not gotten set-up to make the internal splines. Another challenge for another time.It is the universal.

Can you do internal splines with a dividing head on a milling machine? Do you need a shaper also?I considered the universal but figured I'd have my hands full with the semi-universal BS-1. I'll be watching your posts showing the spiral gears you make. I've made a couple of splines but have not gotten set-up to make the internal splines. Another challenge for another time.