- Joined

- Apr 23, 2018

- Messages

- 6,582

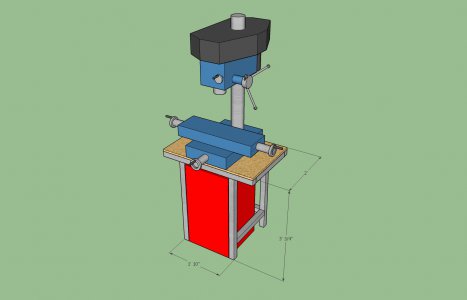

I have the Shars 5" vise, and I think it is perfect. A 6" is way too big, and the 4" is great but just a touch small, so the 5" is Goldilocks.12. VISE (continued)

. Shars has a 5" vise (#202-1001 or #202-1022) Thoughts?

I keep the belts *just* loose enough to be able to jockey the belt with some firm effort. I push the belt to the grove above or below the sheave I'm in while rotating the pulleys a bit so it walks into the next sheave. Easier done than explained, but it is what I do and I can face steel at .040 doc with a 3" face cutter without slipping.13. CHANGING SPEEDS

14. CHANGING TOOLS

Changing tools, I have never owned or made a spline wrench. I use a box wrench on the drawbar, grab and hold a handful of belt, and tighten or loosen the drawbar. Might not sound good, but it works and it's safe as long as the power is off. Again, it's what I do, and I still have ten fingers.

Changing speeds and changing tools on the RF-3x are the reason I bought a mill with a power drawbar and a variable speed head. It's a pain, and I employ techniques to make it less so. Jockeying the belts around works just fine, and holding the spindle by using the belt does too.