- Joined

- Sep 29, 2017

- Messages

- 2,251

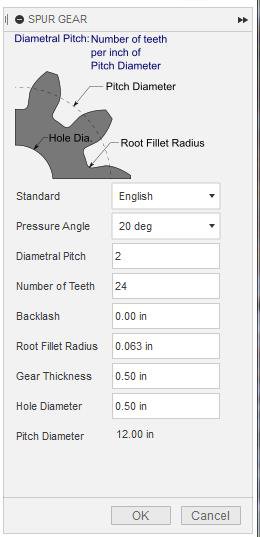

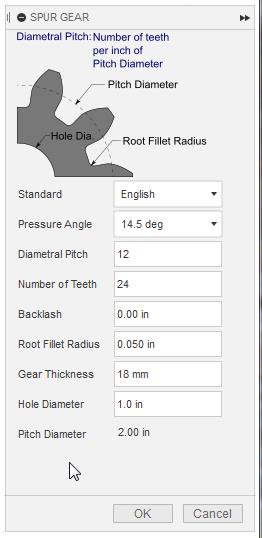

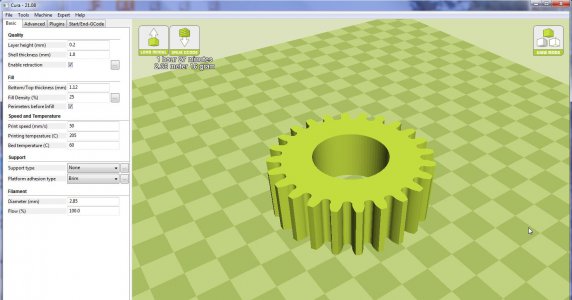

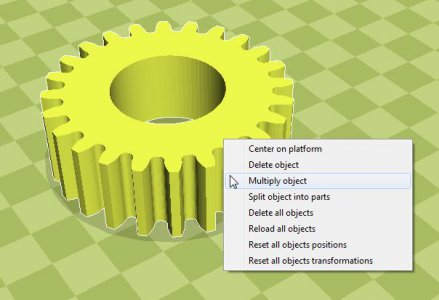

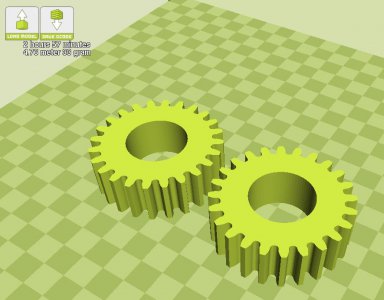

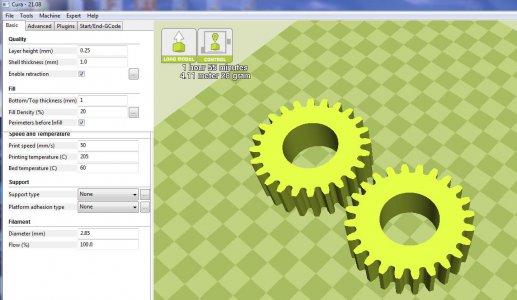

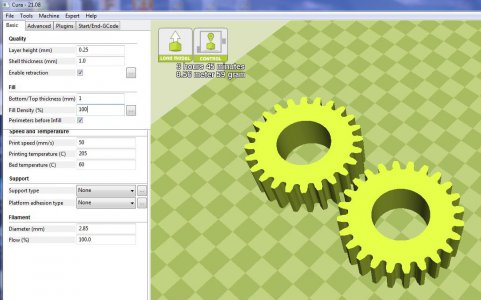

Brian you don't have to print the 28 tooth gear,I found it. But I just saw in an artical that sometimes you need two 24Tooth gears,but I am not sure. What do you think?

I am still struggling to work out the gear sizes for the gear train I need for the 34 tooth helical gears I must make with a 16° lead angle. I've seen so many formulas lately,my head is spinning. Do you perhaps have a formula for this? Stop me if I am getting annoying

I am still struggling to work out the gear sizes for the gear train I need for the 34 tooth helical gears I must make with a 16° lead angle. I've seen so many formulas lately,my head is spinning. Do you perhaps have a formula for this? Stop me if I am getting annoying