- Joined

- Nov 14, 2016

- Messages

- 3,006

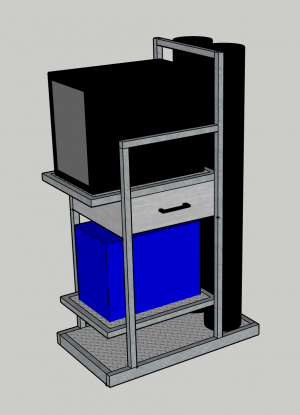

All of the welding carts I see have small wheels in the 3-5" diameter range, suitable for rolling on concrete or asphalt although a pebble or nut can easily jam a wheel. I would like to see some designs with larger diameter pneumatic wheels suitable for wheeling across rough surfaces and yards.

I put 8" pneumatic casters on mine for exactly that reason. I'm not going to be home until next weekend but I can get some photos then.