- Joined

- Aug 6, 2015

- Messages

- 3,908

Yeah baby! Yeah!

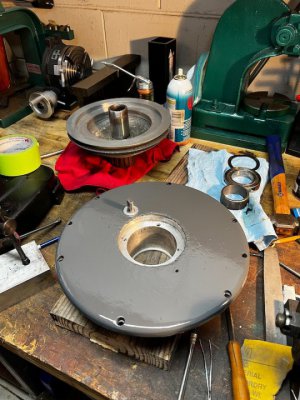

Do not mind the mess... Before watching the video and trying to tippy-tap-tap it out, I was trying everything... so I used WD-40, way-oil, some heat… Made a mess inside...

None of that matters now, it is out!!

The brake band needs a good degreasing, yikes

Now to clean all this mess and get it all looking like new again.

Do not mind the mess... Before watching the video and trying to tippy-tap-tap it out, I was trying everything... so I used WD-40, way-oil, some heat… Made a mess inside...

None of that matters now, it is out!!

The brake band needs a good degreasing, yikes

Now to clean all this mess and get it all looking like new again.

Last edited: