- Joined

- Aug 6, 2015

- Messages

- 3,886

I would think you don't need the brake if you have the tool. It's doing the work for you. I could be wrong, but that's what I think.

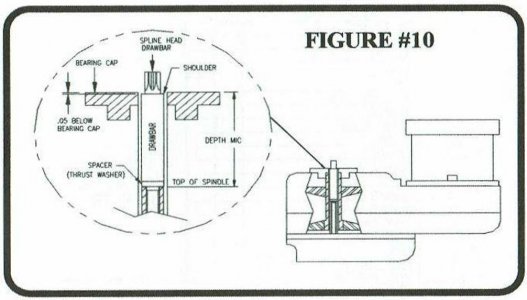

I thought about that... then about machining the drawbar to correct length... then about making a shim to go between the Maxi Torque-Rite and the base plate to compensate for the raise the cartridge bearing locknut with the pulley shaft

But by then I was just too scare to tackle it all... Yeah, I am obviously missing an adapter...