- Joined

- Sep 8, 2019

- Messages

- 4,392

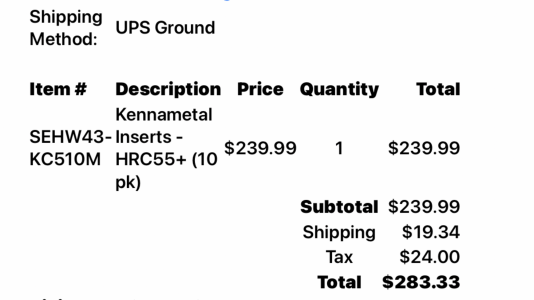

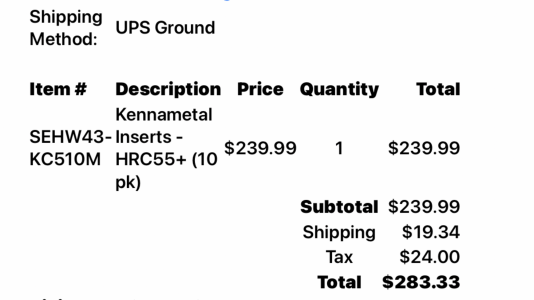

1 box which contains 10 Kennametal SEHW43-KC510M inserts. Painfully expensive at $283.33, or $28.33 landed cost for each insert.

These are for a Glacern face mill. They will be used to face a large amount of 5/8” plate that was used for stick welding practice, so the plate is covered with rusty 60-70 kpsi tensile strength stringer beads.

After being machined, this plate steel will be 8” X 5” plate welding coupons.

These are for a Glacern face mill. They will be used to face a large amount of 5/8” plate that was used for stick welding practice, so the plate is covered with rusty 60-70 kpsi tensile strength stringer beads.

After being machined, this plate steel will be 8” X 5” plate welding coupons.

Last edited: