- Joined

- Nov 30, 2022

- Messages

- 105

Ditron rocks! Question, why glass rather than magnetic?

John

John

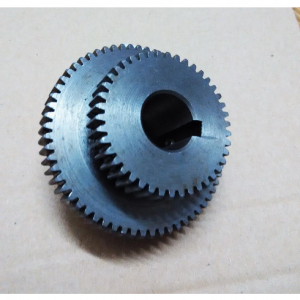

As I mentioned, there's still a plastic gear in the drivetrain at the motor so no worries. One sacrificial link is just good design, two is bad design that ultimately leads to unnecessary failures.Just a word of caution when replacing gears. Most machines have a sacrificial gear that will strip or otherwise be destroyed in the event of a crash. The part is designed to break before damage is done to more critical parts like the spindle, carriage or lead screw. My Sheldon has a phenolic gear in the drive train primarily for that reason. It also helps quiet the drivetrain.

Not sure who you are asking. But for myself, I bought glass because it was self contained and lower cost.Ditron rocks! Question, why glass rather than magnetic?

John

may be wrong, but I think that is an old tire machine standOver the weekend, I met a man who had some machine pedestals for sale.... I came home with two...

A Baldor grinder stand...

View attachment 445588

And an unknown stand that I'm planning to mount a vise on...

View attachment 445589

The vise wasn't included. Does anyone recognize this stand? I'm curious what if originally fit. It is similar to the old Porter-Cable stands, but the ones I've found pictures of all had the company name cast in the base...

-Bear

oh man Bear you have to make use of that foot pedal. Mount it so that the foot pedal can attach to a cord and tighten the vise when you are holding the item to be clamped and need a helping hand... I'm thinking a tool to add that is like the old starter cords to lawn mowers where you wrapped it to start it. use a hook to catch that bale on the pedal and a pulley you can slide over the screw and catch the handle..Over the weekend, I met a man who had some machine pedestals for sale.... I came home with two...

A Baldor grinder stand...

View attachment 445588

And an unknown stand that I'm planning to mount a vise on...

View attachment 445589

The vise wasn't included. Does anyone recognize this stand? I'm curious what if originally fit. It is similar to the old Porter-Cable stands, but the ones I've found pictures of all had the company name cast in the base...

-Bear

View attachment 445589

The vise wasn't included. Does anyone recognize this stand? I'm curious what if originally fit. It is similar to the old Porter-Cable stands, but the ones I've found pictures of all had the company name cast in the base...

-Bear