-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

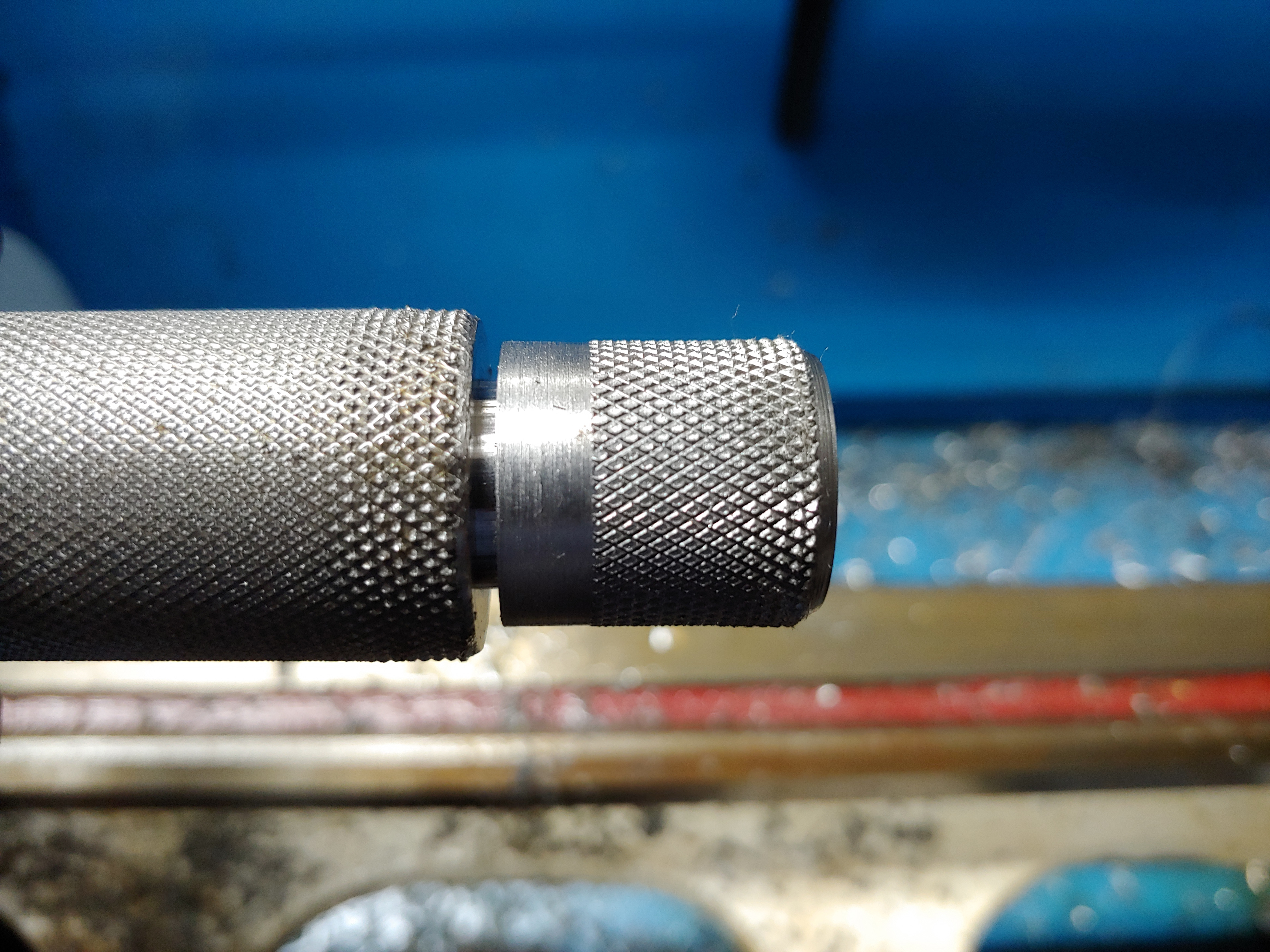

1st,& 2nd knurl

- Thread starter Aukai

- Start date

- Joined

- Oct 4, 2016

- Messages

- 7,021

I was going to part this off, but turned it instead, and did a short power feed on, and manual back off. I then turned it down again, and did a static impression with only moderate pressure, and confirmed my thoughts, unequal impression. Before I tried to do the static impression I checked dimensions, no taper. I was going to try another run, that's why there is a small shadow on the leading edge. So what is causing me to not have a flat equal impression? I am using a 1-2-3 block to square the tool post to the chuck.

- Joined

- Apr 28, 2014

- Messages

- 3,590

On the aluminum, brass, and copper I did up, I'd disengage the feed and stop when I got to the desired position, change the direction, start it back up, increase the pressure while using a mirror to see it, and then engage and go back to the beginning.

A double pass so to say.

A double pass so to say.

- Joined

- Oct 4, 2016

- Messages

- 7,021

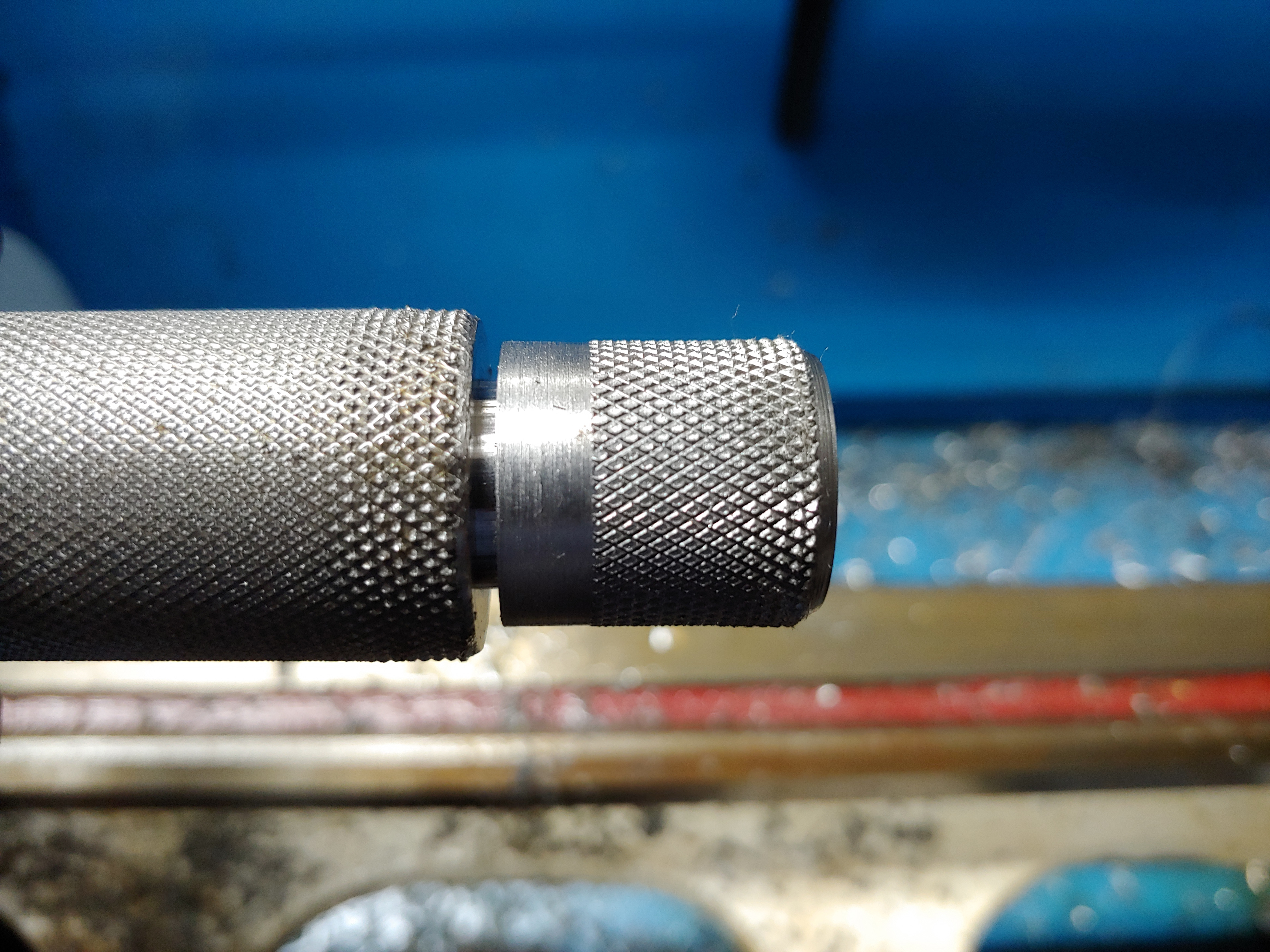

I think it's optical Mike, that piece measured out over the short length. I parted that off, and did a longer piece, I'm only using a dial caliper, but it's measuring out. This episode was back, and forth passes, with tightening at the turn. It appears to make a better looking knurl, like I said it is an unidentified type of steel. Keep practicing, pau for tonight.... Well it seems the left end is still under developed, I'll DTI the shaft for a better reading tomorrow.

- Joined

- Apr 28, 2014

- Messages

- 3,590

Knurling in paradise on a Sunday night.

One was loose before this last pass, both were tight for this one though.

OK, going out, and erasing these, and give it a try

OK, going out, and erasing these, and give it a try