- Joined

- Nov 27, 2012

- Messages

- 7,855

I agree with Mikey. I too try to knurl in the least amount of passes possible to avoid/minimize flaking. I'm usually able to knurl Ti in one pass with my lathe so non-ferrous is no problem either for me.

90% full form is recommended cause it very easy to overshoot 100% depth and as far as functionality for grip, not needed. 100% can be too coarse on the hands for a coarse pitch knurl.

When you overshoot 100% it drastically reduces (damages) the quality of the knurl as it's trying to roll over the peaks. This extra material that gets displaced will roll into the workpiece. It can also damage or reduce the life of the knurling wheels.

With a knurling tool, feed is by eye, there is no dial or a means to measure how much feed on the wheels & the amount to feed varies depending on the work piece diamater & knurling wheel pitch.

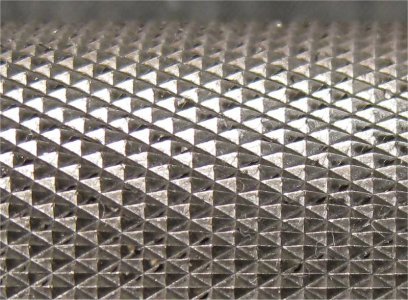

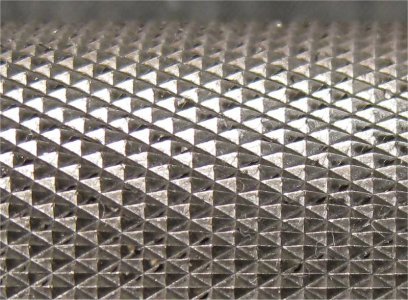

Here's one of my first knurls on Ti done with 2 passes. You can see some of the flaking. This type of flaking is usually seen on harder materials. I suppose they can be picked out but would be very time consuming I imagine. As Mikey stated aluminum flakes like crazy but looks different & will usually get rolled into the work piece making it look like crap.

90% full form is recommended cause it very easy to overshoot 100% depth and as far as functionality for grip, not needed. 100% can be too coarse on the hands for a coarse pitch knurl.

When you overshoot 100% it drastically reduces (damages) the quality of the knurl as it's trying to roll over the peaks. This extra material that gets displaced will roll into the workpiece. It can also damage or reduce the life of the knurling wheels.

With a knurling tool, feed is by eye, there is no dial or a means to measure how much feed on the wheels & the amount to feed varies depending on the work piece diamater & knurling wheel pitch.

Here's one of my first knurls on Ti done with 2 passes. You can see some of the flaking. This type of flaking is usually seen on harder materials. I suppose they can be picked out but would be very time consuming I imagine. As Mikey stated aluminum flakes like crazy but looks different & will usually get rolled into the work piece making it look like crap.