-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

1st,& 2nd knurl

- Thread starter Aukai

- Start date

- Joined

- Nov 27, 2012

- Messages

- 7,855

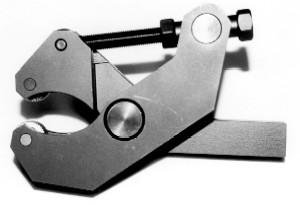

Probably cause they sell their own knurling tools. Not sure if they make their own like the straddle knurling tool pictured above but I'm pretty sure they don't make their own cut knurlers. I have 2 cut knurlers which are identical to the ones they sell but mine are made in Spain.

I don't bother mentioning what tool I'm ordering for, no need really. Just order the size knurls you need

I don't bother mentioning what tool I'm ordering for, no need really. Just order the size knurls you need

- Joined

- Mar 25, 2013

- Messages

- 4,615

Apparently I only build tools, and not much other useful stuff!That would be too ambitious for me.

Robert

- Joined

- Dec 20, 2012

- Messages

- 9,422

Since we’re on the subject of knurling how many passes does it take to get a correct knurl. Is their a specific depth with each type of knurl or is it visual/appearance?

Finally getting back to this thread and noticed nobody discussed this with you.

I don't know that there is a right answer to this but I try to minimize the number of passes I take, especially on harder materials but also in softer stuff. In the former case, this is to reduce the potential for work hardening. In the latter case, it is to reduce flaking. Aluminum and brass flake like crazy so I tend to go for an almost full pattern the first time.

A full pattern produces sharp peaks. Form Roll, the knurl maker, recommends we not go for more than a 90% depth pattern. Going deeper is "abuse", so I try to go for a depth that leaves a tiny flat or crater on top of each peak in a diamond knurl. This is a set and try type of thing and I don't get obsessive about it. I put the wheels on the centerline over and under the work, with the wheels about halfway on the end of the work piece, then I apply some pressure and look for the depth of the pattern I want and also to make sure I don't mistrack. Once I get what I want, I make the full run at once.

I tend to run a bit on the fast side for most things, close to turning speeds for softer stuff but I do slow down for stainless and harder steels. For aluminum and brass, I'm running about 120 SFM and maybe about 50 SFM for steels. I feed by hand most of the time and will feed back out about twice the speed I used to feed in.

I use a lot of lubricant, maybe more than I should, but I'm doing it to lube the knurl and the pins, too.

This works for me.

- Joined

- Dec 20, 2012

- Messages

- 9,422

Most knurls I make are not long, maybe 6" or less, so power is not really necessary. Depending on the amount of pressure I use for that work piece, it is easier for me to control the pattern manually. I feed as fast as the pattern allows. That is, I feed as fast as I can while ensuring I get a full and even pattern. I have found this helps minimize flaking. I manually feed out about twice as fast as I went in. Works good for me.